>> This forum is best when it is useful

and helpful. While there have been many helpful

contributions to this thread, the one above is not one of them. <<

Sorry I didn't meet your expectations. I

will try to do better.

I ask George:

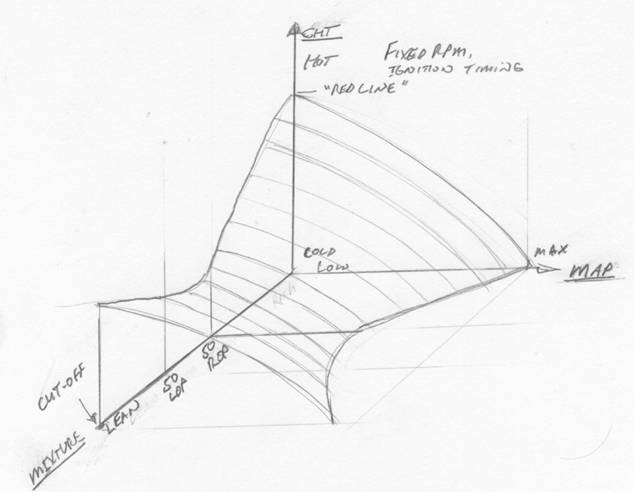

qualitatively is this about right? If not, help us understand what the

real envelope looks like, or let us know if this is a faulty

concept.

The envelope is

useful. However, as you point out:

>>

Note that a given envelope is also

defined by the octane rating of the fuel, RPM, ignition timing, and spark plug

heat range ...<<

And I would add to that, INDUCTION AIR

TEMPERATURE. That one is OFTEN badly overlooked and it is a major

driver WRT detonation.

>> Hot plugs will lead

to detonation at richer mixtures or lower manifold pressure or cooler cylinder

head temperatures. <<

Well... not really. Hot plugs are almost

exclusively a pre-ignition issue, not a detoantion issue. But

then pre-ignition is a much uglier thing than

detoantion.

>> Certified aircraft have

to operate within a broadly defined envelope because the regulators say it must

be so.

However, careful operators don’t go

out to the corners of the envelope. They run cooler, or richer (or leaner)

or with lower manifold pressure, and with ignition timing and such within well

defined limits while using the right fuel. <<

The problem is that I have NEVER seen an experimental

aircraft that had properly defined that "smaller envelope" with appropriate

markings and limitations on the instrument panel.

>> Those that push MAP,

mixture, and temperature outside the smaller envelope created by hotter plugs or

improper timing end up with broken engines. <<

But WHERE are the boundaries of that envelope

???

>> So while Randy may see

trouble with broken engine parts and attribute them to the automotive spark

plugs, I suggest it may be more accurate to say that it is likely that a

particular engine was operated out of its safe operating envelope and

could not handle it. This envelope may well be smaller if one uses

automotive spark plugs. I don’t know. <<

And, with all effort at trying to say this in a low

key manner - - not only do you not know - - but I don't know.

And if I don't know, I am rather certain that very few of the folks

operating their experimental aircraft engines know the answer - - and thus they

continue to operate with the "hope" (not a method) that they

will be "OK".

>> And I suggest that

Grayhawk and others who have experienced no difficulty with automotive spark

plugs have enjoyed no problems because their practices keep them well within

their operating envelope all the time, even if they do not know what the limits

of the envelope may be. And it may well be smaller than with aircraft

spark plugs.

George, does this sound

reasonable? <<

It is reasonable only in the context of two further

constraints: - - the owners really do want to be "experimental test

pilots" and they are comfortable with hoping that they have fully explored

the relevant envelope.

>> Full disclosure: I am

keenly interested to learn more, particularly since I am running an IO-550 with

10:1 pistons, one mag, and one electronic ignition with automotive spark plugs

in the top plug holes. Why? Because Down Under avgas is

US$6.30 a gallon, so 55-60% power LOP is a way of life. I like CHT’s below

320F in the climb, and frequently see under 300F LOP. That is how I try to

stay inside my envelope. If there is a better way, I would like to learn

about it. <<

Two questions:

1) What benefit to you think you get from the 10:1 CR

?

2) Have you marked your CHT with a redline at some

number below 460 d F?

Regards, George