I’ve been working this week on tuning my engine, with lots

of help and phone calls to Tracy. Here is what I have learned.

Tracy, please chime in if I misspeak.

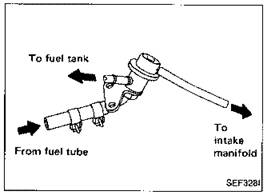

Don’t trust the manuals. Here is the picture from

the Nissan service manual showing how to connect the pressure regulator.

It isn’t correct. The upper barb should be “fuel in”

and the lower barb “return to fuel tank.”

After fixing this mistake, things went a lot better.

The other big lesson for me was that the “6 bars”

for mixture listed in the manual to do the tuning isn’t necessarily the

perfect spot. You need to set a mid-range throttle setting, then adjust

the mixture control until you get the highest RPM. Now look at the

mixture indicator, and use that as the setting for all further adjustments.

For me this was 9 bars.

Lastly, I need to let my engine warm up before making any adjustments.

There is a big difference in performance between a cold and hot engine.

I hope this helps others with their tuning.

If everything goes right, first flight should be this weekend.

Chris Mallory

From: Rotary motors in

aircraft [mailto:flyrotary@lancaironline.net] On Behalf Of Tracy Crook

Sent: Wednesday, May 06, 2009 11:28 PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: Initial Engine Start - EC2 Next Steps?

Actually that order (for piston

engines) is:

Mode 3, 2, 1 then auto tune.

Rotary engines go :

Mode 3,6,2,1 then auto tune.

What was the date of last update or service? Might be able to tell about

the snubber update from that.

Trace

On Wed, May 6, 2009 at 12:02 PM, Mike Fontenot <mikef@apexconsultingservices.com>

wrote:

Tracy,

You wrote:

>>I don't know what software version you have Mike but hopefully you have

the snubber update. (the last thing I want to do right now is more

updates : ) . If you have the new mode 2 (injection dynamic range), do

that BEFORE mode 1 or 9 or autoprogram. <<

I'm at work, don't know what version I have. Where do I find that? I'm

thinking the front of my paper manuals have that written on it. Is there

a function on the EC2/EM2 that displays the version?

I think I do remember reading about Mode 2 in my manual, but I'll have to

check.

Snubber? Never heard of that. Please enlighten.

So are you suggesting an order of:

Mode 2

Mode 3

Mode 9

Mode 1

Thanks,

--

Mike

================================

Mike Fontenot

Apex Consulting & Services LLC

Lakewood, Colorado

303 / 731-6645

mikef AT apexconsultingservices DOT com

================================