|

|

In a message dated 8/22/2007 7:57:15 PM Pacific Standard Time, Lehanover@aol.com writes: I would (will) go with the flat plate. All of the pan bolts are involved. Four Lord style mounts involved. Compact and uses the engine block for added stiffness. I will include the nose gear in my mount to reduce fire wall complexity. Possible oil control benefit. Lynn E. Hanover

Lynn, Well reasoned, but it you use a slightly changed version of the Shertz mount like Jerry Hey is now making the mount uses the bellhousing bolts and fits between the Psru plate and the engine. Using two large lord mounts and that system I believe it's a toss up. I really don't think you can really plan for this though unless you always fly high and carry a 'chute! Bill Jepson

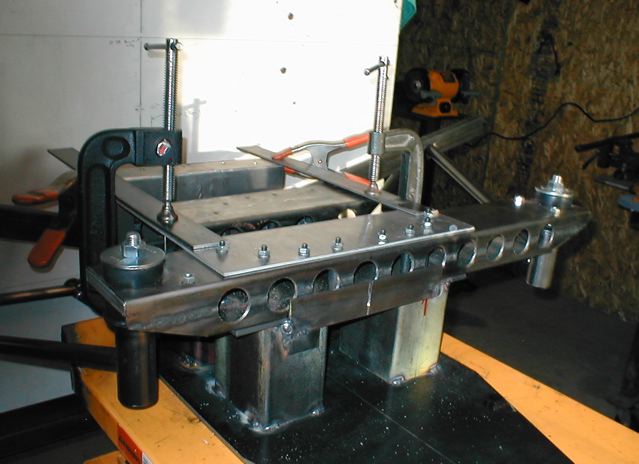

I have not used that design in a long time. The S-beam now is bolted to the pan flange using eight pan bolts at the flywheel end. It is easier to install and does not involve the PSRU at all. I don't think there is a strength issue with either type of engine mount. Here are two pics just shot this morning of a RV7A engine mount under construction. At this stage the pan flange (less the pan) is bolted to the S-beam. The same bolts are later used to attach the S-beam to the engine. This engine mount is asymmetrical, it is extended on the exhaust side to provide clearance for exhaust and is shortened on the cool side to provide room for a cool side rad. Jerry

.

|

|