John,

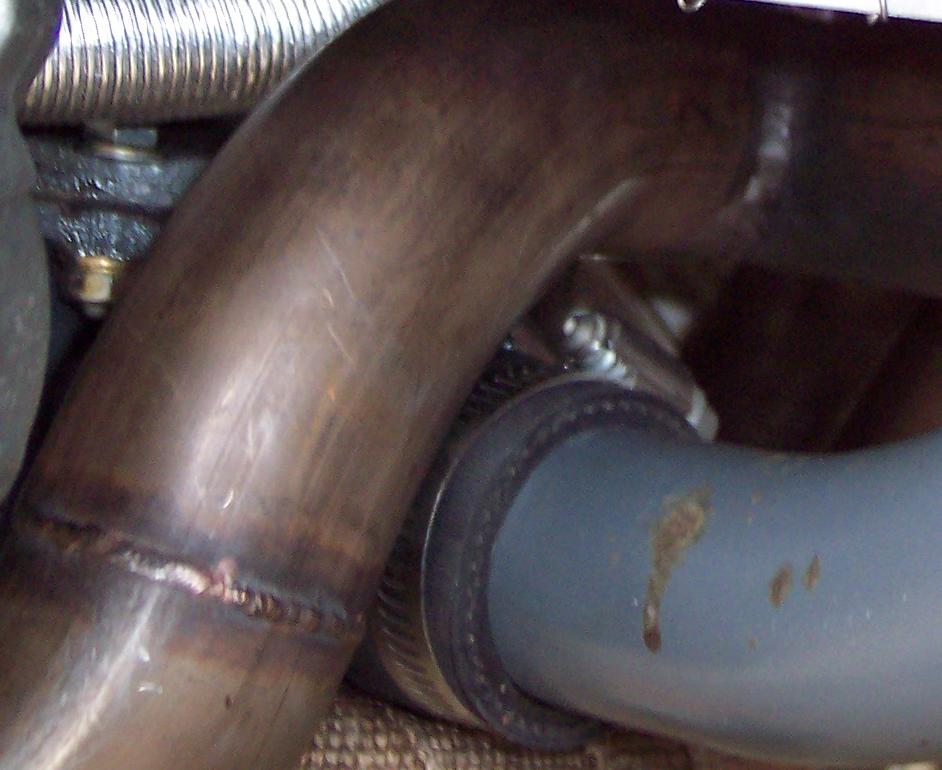

Same situation here with the 320 in the 235 cowl. The exhaust pipe is

very close to the intake tube stub on the sump on #2, so the rubber hose

connection is even closer. I ground down the rubber connection hose

thinner there for a little more space. An alternative is to remove the

exhaust (a big job on this engine) and create more clearance via pipe

massaging in that area. With the exhaust pipe going thru above the

intake tubes and below the bottom of the cylinders for bottom cowl clearance,

space is a real premium for other items like the cylinder baffle safety wires,

cht probes, oil return lines, starter cables, etc.

Gary

LNC2

-----

Original Message -----

Sent:

Wednesday, November 27, 2013 7:53 AM

Subject:

[LML] [LNC2] Intake hose touching exhaust

The #2 cylinder of my O-290-D2 has been a real problem child.

While dealing with the impossible-to-reach inboard exhaust flange nut, I

noticed that the intake hose is actually touching the header

wrap on the exhaust stack which runs below the intake tube, and is very

close to touching the upper exhaust stack. This seems like a recipe for

disaster. Has anyone else had this problem and if so, how did you solve it?

Has anyone tried using silicone rubber hose or flexible metal hose? Does the

exhaust stack need to be reworked? Any suggestions would be very

appreciated.

Here's

a wide-angle shot taken before I installed the intake tube and hose:

P.S. If anybody was

wondering, that aluminum flexible "hose" you see running along the top of the

oil sump is Thermo-Flex,

a flexible high-temperature heat shield which will hopefully protect the

wiring to the starter and alternator. The insulation on the #2 wiring to the

starter was actually discolored due to the heat in that

area.