This forum is best when it is useful and

helpful. While there have been many helpful

contributions to this thread, the one above is not one of them.

We understand that George has spent a lot

of time, sweat, and money developing data and understanding. Much GAMI work

focused on certified aircraft. GAMI has taught us a lot and helped piston

engine operators save avgas and equipment. It is reasonable that George

wishes to keep proprietary, hard-earned information and know-how private and

confidential. However, within those constraints, George, what can you

tell us without compromising your business? How can you help us?

Certified airplanes have to pass

certification tests. As I recall, this includes things like sustained

full power climb at Vy, gross weight, ISA+20 day, without exceeding red

line. In a turbo engine making lots of power in thin warm air, this means

pouring fuel into the cylinders to prevent detonation. In an aspirated

engine, less fuel is required because manifold pressure and induction

temperature are lower, and power decreases with altitude.

With an experimental airplane with

compromised cooling (most of them), sustained climb at Vy is out of the

question. It is different because it is experimental.

We also know that for certified aircraft,

the red line CHT might be 450-460F, and we experimental pilots like to stay

about 100F cooler than this. If you operate within a different envelope,

then things like acceptable spark plug heat range most likely will be

different. George hits the nail on the head when he suggests it is all

about WHERE in the operating envelope you choose to operate.

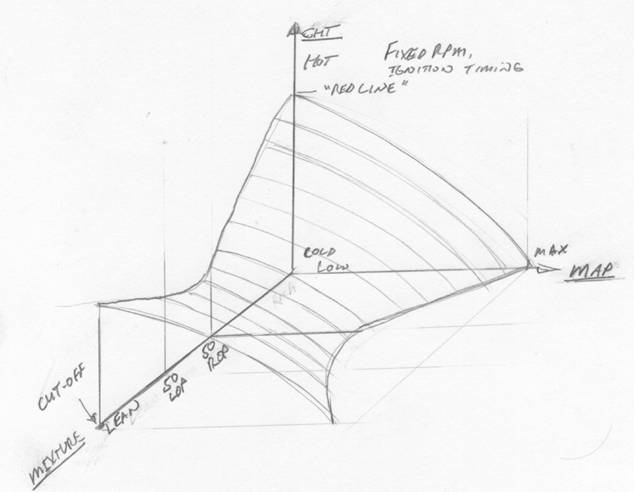

I would like to make a suggestion that

might be helpful. I suggest that operators think about the issues of

detonation in terms of a visual 3-D operating envelope in which the three axes

are manifold pressure, mixture, and cylinder head temperature, variables we

control in the cockpit.

We know that if you run hot cylinders and

a lot of manifold pressure, you had better be rich to prevent detonation. We

know that if you run lean of peak, you can run more manifold pressure without

detonation in part because the cylinders will be cooler and in part because of

the way the mixture ignites and burns. And it seems that pressures

get high and trouble seems to focus around the area where mixture is at peak or

slightly on the rich side of peak.

Give all this, have a look at the sketch

below which tries to illustrate the allowable operating envelope. If you

are inside the envelope, you are OK. Outside and you court disaster in

the form of detonation and perhaps other uglies.

I ask George: qualitatively is this about

right? If not, help us understand what the real envelope looks like, or

let us know if this is a faulty concept.

Note that a given envelope is also defined by the octane

rating of the fuel, RPM, ignition timing, and spark plug heat range. Assuming

that this saddle-shaped solid is roughly right, I would suggest that regarding

spark plugs, having the wrong spark plug, or more precisely, having an

excessively hot heat range, shrinks the envelope. Hot plugs

will lead to detonation at richer mixtures or lower manifold pressure or cooler

cylinder head temperatures.

Certified aircraft have to operate within a broadly defined

envelope because the regulators say it must be so.

However, careful operators don’t go out to the corners

of the envelope. They run cooler, or richer (or leaner) or with lower

manifold pressure, and with ignition timing and such within well defined limits

while using the right fuel. Racers push the envelope on MAP and RPM and

perhaps on timing as well.

Those that push MAP, mixture, and temperature outside the

smaller envelope created by hotter plugs or improper timing end up with broken

engines.

So while Randy may see trouble with broken engine parts and

attribute them to the automotive spark plugs, I suggest it may be more accurate

to say that it is likely that a particular engine was operated out of its

safe operating envelope and could not handle it. This envelope may well

be smaller if one uses automotive spark plugs. I don’t know.

And I suggest that Grayhawk and others who have experienced

no difficulty with automotive spark plugs have enjoyed no problems because

their practices keep them well within their operating envelope all the time,

even if they do not know what the limits of the envelope may be. And it

may well be smaller than with aircraft spark plugs.

George, does this sound reasonable? What can you add

or correct?

I think the key message is: if you deviate from standard

certified aircraft practices and hardware, then your operating envelope could

well be smaller. So you best not push into corners of the certified

airplane envelope if you are running higher compression, automotive spark

plugs, more manifold pressure, more RPM, advanced timing, or whatever.

I hope this view point is helpful. More importantly I

hope it is correct. Comments, corrections, and suggestions always

welcome.

Full disclosure: I am keenly interested to learn more,

particularly since I am running an IO-550 with 10:1 pistons, one mag, and one

electronic ignition with automotive spark plugs in the top plug

holes. Why? Because Down Under avgas is US$6.30 a gallon, so

55-60% power LOP is a way of life. I like CHT’s below 320F in the

climb, and frequently see under 300F LOP. That is how I try to stay

inside my envelope. If there is a better way, I would like to learn about

it.

Fred Moreno