[ photos re-compressed -Rob ]

-------- Original Message --------

Baffling solved?

<<baffling 003.JPG>> <<baffling

004.JPG>> <<baffling 009.JPG>> <<baffling

010.JPG>> <<baffling 013.JPG>> <<baffling

014.JPG>>

I

listened with great interest to the

baffling questions, saw the posts, read Walter’s

responses, understood what

was taught at the Advanced Pilot’s

Seminar, looked at the current baffling in my engine,

drew some conclusions and tried some changes. I

am greatly appreciative of all the discussion and participants.

Disclaimers: I am not an engineer, have no

vested interested in anything but my Lancair and have not bones to

pick.

I have a

TCM TSIO 550 E with Lancair firewall forward kit from late 2000 on

a IVP with 620 hours.

I had

already upped my fuel flows at WOT to 43 gph. I

also see 32 gph at 2500 rpm and 31”

MP. (This is a critical part of keeping the engine cool as the TCM

settings are most likely too low of fuel flows to keep the engine cool. I

learned this from George Braly.)

Problem:

Number 2 and 5 run hotter. Can’t

climb at full power more than a 4-5 minutes before the head

temperatures start climbing excessively,

esp. #5.

Problem:

The barrels come

to the edge of

the cooling

fins on all cylinders at the biggest finned area

about 2” wide..

This is a problem on number 2

and 5 where the baffling is tight against cylinders

blocking airflow over the 2”.

Solution:

Get more air around the front side of #5 and the rear side of #2.

Picture

003 and 004 shows the swaging of the

baffling of #2 cylinder. 003 is the cylinder side

and 004 is the inside of the oil plenum. I did not want to cut a

hole and violate the plenum for the oil cooler. If I had

cut a hole as seen on an earlier post I had no clue what this

would have done to the airflow or my ability to control the

oil temp. The swaged area is 2.125”

wide and 3.5” tall and ¼” in

depth at the center. Picture 009 is

the pattern used in creating the cavity to

shape in a board. I

pounded the aluminum with curved oak piece of hand railing. Note

also that I beveled the walls and clamped the baffle to the board

with angle iron.

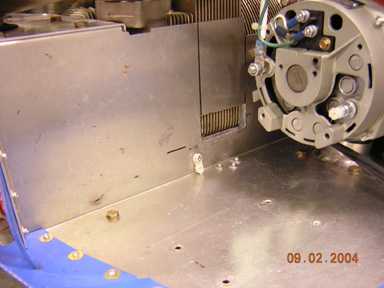

Picture 010

shows the hole I cut in the front baffle of #5.

The hole shown is 1” x

2.125” and is too big. I

subsequently covered ½

the hole so it is now ½” by

2.125”. This seems to be about right, perhaps

still a little cooler than it needs to be.

If you are wondering how I cut this, I did not remove the baffle or

the alternator. I used a dental high speed handpiece with a fluted

carbide burr.

(Nice to have a dentist/son in

the family.) About 10 minutes to make

this mod. Picture 013 Now

look at what Lancair has done on their production baffling for the last

8 months. Their hole on #5 is

higher than mine. The top of

the hole is just at the point where the barrel of the

cylinder closes off the air from the cooling fins. I like their

solution better. Picture 014 They have

also moved the oil plenum

behind #2 rearward about ¼” and modified

the other attached baffling to

reposition it back to the cylinders.

I suspect that this is a very good solution also. Maybe someone on the

list flying with these mods can share how these work.

Results:

I can now climb full power to 13,500 with the highest CHT at 340

degrees. 150-155kts IAS, 1800-2000fpm

(This is as high as I have climbed since the mods last week.) I

will test this to FL 240 in

a trip later this week. In cruise at

8500’ 32”MP,

2470 rpm, 17.2 gph, OAT 10C, TIT 1522

EGT/CHT

1 1578/316

2 1540/296

3 1560/288

4 1512/288

5 1540/275

6 1446/296

Carl Cadwell

Cadwell Laboratories, Inc.

909 North Kellogg Street

Kennewick, WA 99336

1 800 245 3001

509 735 6481

Fax: 509 783 6403

Email: carlc@cadwell.com

www.cadwell.com

www.quickmed.com

baffling 003.JPG

baffling 004.JPG

baffling 009.JPG

baffling 010.JPG

baffling 013.JPG

baffling 014.JPG

|