|

|

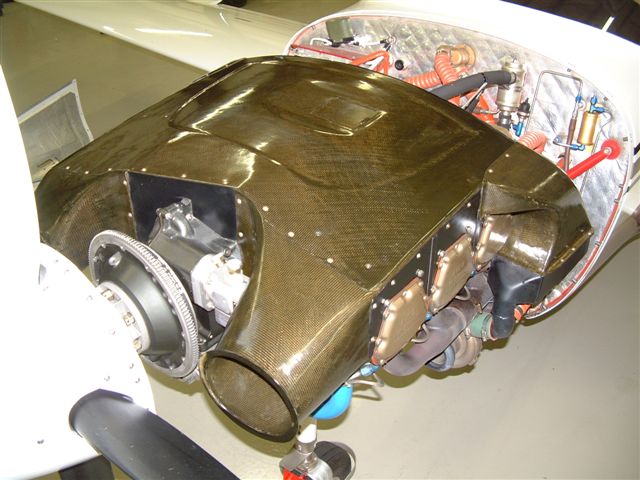

The attached pictures show the plenum on N170BR. The

composite elements are 3 bid E-glass and 1 bid carbon with the

occasional foam and 2 bid carbon stiffener. I used standard Jeffco

epoxy which has shown excellent heat resistance. I made the inlet and

intercooler ducts by carving male plug molds in high density foams,

coating the plugs in car wax and applying a 2 bid layup. I removed the

shells from the molds and then applied another bid of glass followed by

one bid of carbon. The carbon makes a dramatic improvement in stiffness.

The large top cover piece was molded using the inside of the cowling.

The final weight of the cover was about 1.4 lbs, less than half the

weight of the silicone perimeter seal and fasteners that you would use

in a conventional installation.

My engine is based on a Lycoming IO540 K series. It has a large

capacity oil pump, long plug angle valve cylinder heads and 8.5:1

pistons. It produces its rated 350 HP at 2700 RPM and 35" (dynamometer

tested). You can see another picture of my engine in almost any

Trade-a-Plane in the Barrett Performance Aircraft ad.

During climb I fly at Va ~175 KIAS, 29 GPM, 87% power (300 Hp), 1000

FPM average to the mid 200 flight levels. CHT NEVER exceeds 400 degrees

F.

In cruise I run 2500 RPM, 28 inHg, 21 GPM (150 ROP), 1500 TIT, 390 CHT

(+- 10 degrees).

During races I run at 104% rated (takeoff) power. I run the engine

relatively hard all the time and always at 75% in cruise. At 845 hours

TT the engine has the same compression as new (mid 70s).

The big secret in designing an effective plenum is no big secret at

all. Make it tight. Seal all cracks, gaps and holes that do not

directly cool the engine. Remember that there will be nearly 1 PSI

deforming the plenum in flight. Many gaps enlarge under pressure,

bleeding off precious cooling air just when you need it. Remember

that silicone perimeter sealing "belting" is not very effective,

especially at the corners, and all those little gaps add up.

Regards

Brent Regan

N170BR-1.JPG

N170BR-2.JPG

N170BR-3.JPG

N170BR-4.JPG

N170BR Engine LF HR.JPG

N170BR Engine RF HR.JPG

N170BR Engine RR HR.JPG

|

|