okay I found a good company called SPD Exhaust. They have everything you need in 321ss.

With the engine being an RX8, we have three exhaust ports. Should I weld the front and back solid to the muffler, and make the middle one a slip fit for expansion? Or vice-vesa?

- Matt Boiteau

On 2019-12-28 11:03:42 AM, Finn Lassen finn.lassen@verizon.net <flyrotary@lancaironline.net> wrote:

I did something similar with my RV-3

13B decades ago. It split open at the welds around one of the

pipes from the manifold into the the big outer tube. True, it did

use individual manifold base plates, not the connected factory

manifold and the big tube was only 0.035.

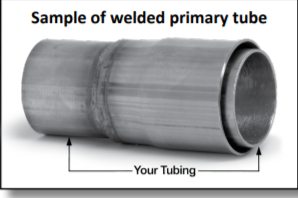

Still, I would recommend slip joints on two of the three pipes,

like I added on one of the pipes (cut through and a surrounding

bigger pipe -- missing in picture).

Can't remember why I went from the above to individual runners

into a perforated pipe under the fuselage. Probably got lured by

promise of increased power by tuned lengths and still

uncomfortable by the muffler being inside the cowling.

Finn

On 12/28/2019 12:10 AM, Matt Boiteau

mattboiteau@gmail.com wrote:

This is

what I'm going to try in a few weeks.

"

Exhaust valve opens

and a pulse of hot gas puffs out through a short pipe, then tangentially into a cylindrical canister. Being tangential, the

pulse flattens out and travels helically (rather than bouncing

and reverberating around) along the inside curved wall of the

can, spiraling toward the exit, where it comes out more

uniform in flow and so pretty quiet."

Outer pipe = 321 ss 0.050 thick. Flat plate bent to a 5"

tube

Inner pipe = 321 ss 0.036 thick. 2.5" diameter

(I might use

302ss 0.065 since I already have it)

From my understanding, the area of the holes should be

double the area of the inner pipe.

- Matt Boiteau