|

Hi Bryan,

Here is a link to a web page which does a better

job of explaining the use of pulse tuning and I think addresses the problem

closer to what a PP intake might involve - using a plenum(s) rather than

attempting to interconnect the two intakes.

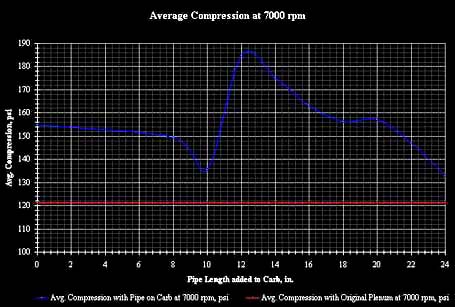

This page provides a graph which shows the dramatic

increase in compression pressure when you hit the sweet spot in Pulse

tuning

One thing to keep in mind is this analysis is

directed at at 4 stroke pistion engine and not the rotary - the principle

diffierence is the rotary engine provides twice the frequency of excitation at

the same rpm of the piston engine. This can be a factor in some of the

equations.

In any case, their experiment with pulse tuning

resulted in this conclusion -

From the results of the experiment, it was clear that the increase

in VE due to the pulse effect of the primary pipe is between 10% and 15% at 7000

RPM.

The Mazda DIE approach is a bit different in that

instead of an open (plenum) at the end of the tube and the need to wait the time

to have the pulse reflected back to the intake port, the rotary instead

has another intake port. This means that for the for the Mazda DIE effect

the tube can be 1/2 the length calculated for a port-to-plenum back-to-port

arrangement as you would have in a PP set up.

There are other factors that can shift the rpm

sweet spot that are tough to quantify without a computer program (they do exist

for around $600 the last time I checked) that can run on a PC.

Ed

Ed

----- Original Message -----

Sent: Monday, June 21, 2010 10:41

PM

Subject: [FlyRotary] Re: Pulse Tuning

[FlyRotary] Re: 13B rotary engines

Thanks

Ed,

Now that you mention

it, I recall seeing an engine with a very long intake at about a 45 degree

angle. I think it was only for a dyno run. Unusable for just about

any application due to itsí length.

I need to re-examine

that Renesis manifold.

Bryan

From:

Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On

Behalf Of Ed Anderson

Sent: Monday, June 21, 2010 10:03

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Pulse Tuning

[FlyRotary] Re: 13B rotary engines

BW, as best I recall (don't have a

Renesis) that small chamber is simply a "transfer chamber" to get the pulse

from one intake tube to another.

The DIE effect that Tracy mentions relies on

a type of pulse called a "Finite Amplitude Wave (FAW)" - this wave behaves

different from traditional sound waves and makes a 125 db sound wave seem lik

a very tiny soundin comparison. These wave shatter metal not to mention

ear drums.

There are several "tuning"

techniques which attempt to make use of these Finite Amplitude waves in

induction systems. Mazda has been one of the most successful attempts in

part due to its unique construction (no valves) and the rapid generation of

these waves in the intake. In the older 13B anytime the intake port

opened, the still present exhaust gases would burst forth and produce a shock

wave ( FAW pulse). If the intakes were tied together and of the

proper length - at a specific rpm the pulse generated by the opening of the

intake of one rotor would travel through the intake to the intake of the 2nd

rotor. It was designed to arrive just as the intake port was

closing.

When an engine (piston or rotary)

starts its compression stroke, the intake remains open for a period - during

this period the compressiing piston/rotor pushes out some of the mixture its

already "sucked" into the chamber. Typically the value for this mixture

pushed out during this "Reversion of flow" amounts to around 15% of the amount

already "sucked" in.

So if the FAW Pulse arrives at the

right time most of its dynamic energy is converted from kinetic energy to a

localized increase in pressure right beside the closing intake port. If

all goes well it prevents most of this reversion. In fact, Mazda found a

15% increase in HP at 6000 rpm using this

knowledge.

However, it is generally only

significant for one rpm - or if you do like Mazda and have a valve to change

the length of the intake for this pulse, you may get two sweet spots at a

lower and a higher rpm.

Since PP are not interconnected

the approach Mazda used on the N/A 13B side ports won't work as

is.

However, due to the properties of

the FAW pulse when it encounters a change in cross sectional area, the pulse

tuning technique could theoretically be used on a PP. Since you want a

increase in pressure as the port closes, and since the FAW pulse will reflect

from an opening into the atmosphere (Plenumn box also) - if you made your PP

tube a specific length then at some rpm (which can be calculated) the pulse

will bounce back from the plenumn and reach the intake port at exactly the

correct time.

That said when one makes the

calculations (as best I recall from a few years ago - so don't hold me to

exact figures), you would find that say for the peak to occur at 6000 rpm -

your PP tube would need to be around 48" long. High target rpm would

result in smaller lengths required.

Then again, that length (whatever

it is) is only good at one RPM to get the

effect.

In my case, I spent 3 months just

doing the analysis to derive the equations for the old 13B. Since my

primary objective was power on take off - (I really don't care about top speed

as I don't fly there - too expensive {:>)), I did not mind the restriction

to one rpm.

So my DIE intake is tuned to give

maximum power at around 6000 rpm (My static for take off swinging a 74x88

prop). I may get up to 6200 rpm static on a colder day as the sweet spot

is a function of the speed of sound (among other things) which changes

with OAT temperture.

In my opinion (and that is all it

is), if I were going PP, I would probably not spend much time considering DIE

(or Dynamic Chamber -- which is not quite what most people think it

is).

----- Original Message -----

Sent: Monday,

June 21, 2010 8:38 PM

Subject:

[FlyRotary] Re: 13B rotary engines

Thanks Tracy,

I didnít realize

the plenum would have that effect.

The stock Renesis

seems to have a chamber prior to the valves that create the DIE, but I guess

it is too small to be called a plenum chamber.

BW

From:

Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On

Behalf Of Tracy Crook

Sent: Monday, June 21, 2010 8:12

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: 13B rotary

engines

I

hate to ask, but what about the Dynamic Intake effect in the PP with a

traditional log-type manifold?

If you

think about the meaning and function of the Dynamic effect, you will see

that it is mutually exclusive with the traditional log-type

manifold. the 'log' is a plenum chamber which inherently damps

out the dynamic waves and reflections in a DIE intake system.

The

timing, length, etc would be different than for the sideport DIE setup that

Ed Anderson did so much work on. I won't even pretend to have any idea

what the proper parameters are for a PP DIE setup.

Tracy

On Mon, Jun 21, 2010 at 7:44 PM, Bryan Winberry

<bryanwinberry@bellsouth.net>

wrote:

Yeah,

I just saw those MP

taps for the oil injection on another site. Iím no expert, but that

seems like an odd place to gather MP data.

I only asked about

the slide throttle, I certainly had not decided that it was the

answer.

Sounds like you

recommend the traditional TB Ė manifold Ė runners setup for the PP as

well.

I hate to ask, but

what about the Dynamic Intake effect in the PP with a traditional log-type

manifold?

Bryan

From:

Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On Behalf Of Tracy Crook

Sent: Monday, June 21, 2010 7:29

PM

To: Rotary

motors in aircraft

Subject: [FlyRotary] Re: 13B rotary

engines

I have purchased

the EC-3. Will this make any difference in the difficulty of

tuning? Is it a good choice for a PP

setup?

Iíd imagine I

should aim for around 7500 rpm for a

RD-1C.

Bryan,

Mark (the Mustang II w/ pp 13B) used an EC2 on his engine and eventually got

it running pretty well but it was a MAJOR pain getting it to work with that

slide throttle since getting manifold pressure was hard to do since there IS

NO MANIFOLD when using that slide right at the port. No one seems to

consider these 'details' when planning their installation. I'm of the

same opinion as Bill on the slide throttle- Why the hell do it?

Mark eventually got a usable MP signal by taping into the oil injection

ports in the rotor housing but that's not ideal.

BTW, several

people referd to Mark's PP 13B as a Renesis PP but I thought it was a 2nd

gen 13B. I could be wrong. Pity that the airplane was lost in

that ground accident, I had not heard about that.

Tracy

On Mon, Jun 21, 2010 at 7:13 PM, <wrjjrs@aol.com>

wrote:

The importance of

any system that you use will be, DO YOU UNDERSTAND IT? Have you ever

tuned an engine using a carb, or FI yourself? Tracy's system seems

like a good one for the price. I have not used Tracy's EMS but it has

been effective for the guys that keep at it. A good fuel flow and mixture

meter are top tools for determining where you are. I believe those are built

into the EC-3. Remember, while it won't be changing while you run the

engine, the intake and exhaust are just as "active" parts as ignition and

injection. My advise would be to be sure that you triple check all your

wiring before you install it. Too many of the guys have run into problems in

their wiring. Be sure you are dealing with a genuine tuning problem and you

will be miles ahead.

I have purchased

the EC-3. Will this make any difference in the difficulty of

tuning? Is it a good choice for a PP

setup?

Iíd imagine I

should aim for around 7500 rpm for a

RD-1C.

-----Original

Message-----

From: Bryan Winberry <bryanwinberry@bellsouth.net>

To: Rotary motors in aircraft <flyrotary@lancaironline.net>

Sent: Mon, Jun 21, 2010

3:50 pm

Subject: [FlyRotary] Re: 13B rotary

engines

I have purchased

the EC-3. Will this make any difference in the difficulty of

tuning? Is it a good choice for a PP

setup?

Iíd imagine I

should aim for around 7500 rpm for a

RD-1C.

As a reference the

original Powersport 13B P-port is rated at 210 HP normally aspirated. The

fuel flows are very similar to any other engine producing that level of

power. Steve tells me that they were seeing FF very comparable to an angle

valve IO-360 producing identical power. This engine was dynoed with

butterfly valves in the housing. These p-ports were 1-5/8' diameter

optimized for 6000 RPM. The engine would rev higher but you were already at

peak power anyway. Larger ports will make more power at higher RPM. Tuning

will become more critical with the larger ports. A personal anecdote

here. I built a high reving motorcycle engine in 1978 with all the "best"

parts at the time. The engine was unreal at high revs, but if you

transitioned to anything below 4000 RPM by shutting the throttle off and

quickly opening it again the engine would "catch" or hit an RPM

plateau and would rev no higher. In fact the engine would die if not

returned to idle! This horrible malfunction was TUNED OUT later, and the

solution was surprisingly simple, however difficult to find. The key

here is that many people underestimate the job of installing and tuning

p-ports. There are two aspects, first the initial install being sure there

are no leaks . Then second, and most overlooked is that the system must

tolerate the heat cycles of a high power engine without DEVELOPING NEW LEAKS

for a long time. Powersport used an insert with o-rings sealing the port.

O-rings or other elastomers work much better than epoxy on long-term sealing

because there are different expansion rates between the port and the epoxy.

On a car you can usually get away with epoxy for a while. An aircraft

is a different animal. The aircraft engine needs to tolerate 80-100%

power for long periods and then long cold-soaks on the ground. The

rotary is mechanically tough enough but you need to design your subsystems

like a race car that will see a 500 mile long straight-away! When

Paul Lamar ran one of the newsletter guys P-port Renesis at MazdaTrix, They

got great numbers, but only after changing to an intake that MazdaTrix had

spent lots of time tuning. P-ports will run great, and even idle well if not

too oversized, but don't expect the tuning to be real easy. Remember you are

designing a new intake, exhaust, and the equivilent of a new cam timing all

at once. The rotary is very much like a two-cycle in that respect. The

results can be very worth while if you understand the difficulty

involved.

Not all P-ports

are equal.

Talk to Bill

Jepson ( on here) about availability of new

P-ports.

All this talk of

additional power coupled with an easier intake design has me thinking I

should probably go this direction with my Renesis. Itís still on the

stand after rebuild.

I havenít

constructed the manifold yet

anyway.

I assume fuel

flow will be higher than normal?

Is slide throttle

best option?

Need to search

archives I guess.

From:

Rotary motors in aircraft [mailto:flyrotary@lancaironline.net] On Behalf Of Lynn Hanover

Sent: Monday, June 21, 2010 12:15

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: 13B rotary

engines

In a message dated 6/21/2010

11:03:01 A.M. Eastern Standard Time, rv-4mike@cox.net

writes:

Thanks for

the feedback Lynn. Unusual to see a "poor port

design" actually aid

performance.

It is not obvious until you start

graphing the open and close events, but the side port which uses the side

of the rotor as a shutter to open and close the port, offers Mazda great

latitude in port timing. In the periphery ported engine (both ports)

it is impossible to arrive at zero overlap, and have an engine that will

produce any power at all. The apex seal does not close off either port at

all, it just valves gasses in one direction or another.

In addition, the overlap of the

periphery ported engine is far more effective flow wise than overlap in

the side ported engine. One apex seal is above the intake port when the

opposing apex seal is below the exhaust port. Flow between the two is

unobstructed.

So, at low RPM you get fresh mixture

leaving through the exhaust port, and combinations of burned and unburned

fuel and exhaust gasses flowing partway back into the intake

runners.

This reduces the low RPM output to

the point that the engine seems quit docile, and is easy to drive around

in the car, slowly, or possibly taxi in an aircraft. This would make

off idle tuning data useless as there will be fuel burning right on top of

the EGT probes, and unburned fuel reaching the F/A sensor.

The engine will act along the

lines of a piston engine with a long duration cam. When the engine reaches

its happy RPM where all of the mixture is burning inside the engine, it

will step up on the "CAM" and you will

see what a good idea this was. Use slow throttle inputs until you find the

"WOW" RPM, and be ready with all available rudder.

When we first ran a factory

periphery port engine, we found that there were places on the track that

would not allow full throttle. This with 11" wide slicks. Thank Heaven for

rev limiters. The driver reported the rear end getting real loose cresting

hills and bumps.

7000comp_graphsmall.jpg

|