I had a bit of a setback on my scoop. I opened up a box

of foam last weekend only to discover that the wrong dimension material was shipped

(2 inch vs. 3 inch.) The supplier bent over backwards and shipped me a replacement

so I’m off and running again.

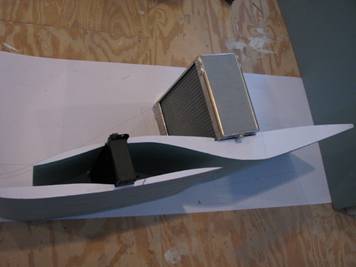

I started by blocking out two

of the areas that frame the top and bottom of the oil cooler area (which also

makes up the floor of the radiator ducting. 3lb PVC foam is used to avoid any

damage that might occur in the event of a fluid leak. You can see how this lays

out on a full size plot/drawing of the plan.

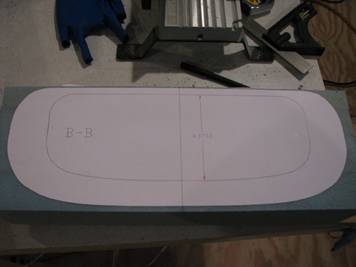

For the scoop, it’s a

matter of converting my 2D drawings into a 3D reality. I started by plotting

out the bulkhead drawings. I then figured out the dimensions of the foam

material required to block out each bulkhead section. Here I’m working on

[B-B] to [C-C]. I used a hand miter box saw to insure the greatest accuracy and

cut the various pieces.

I used 3M 77 spray adhesive to glue

the parts together. Some foams really don’t like this stuff but it’s

safe to use on the PVC foam.

Once that is complete I glued

my bulkhead drawings to the foam. This is my cut line (inside and out.)

As each segment is cut and

shaped, they are stacked, glued and then sanded again to blend the transitions

between segments. Below is the shaped [A-A] to [B-B] segment stacked on the next

(yet to be cut) segment [B-B] to [C-C].