|

|

Rotary Engine wrote:

Oh; yeah. I also tried VGs about 2 1/2 ft in front of the exit fairing --

no noticeable effect. I had previously tried smaller VGs on top of the

exit

fairing for no joy.

Al

Hey Al,

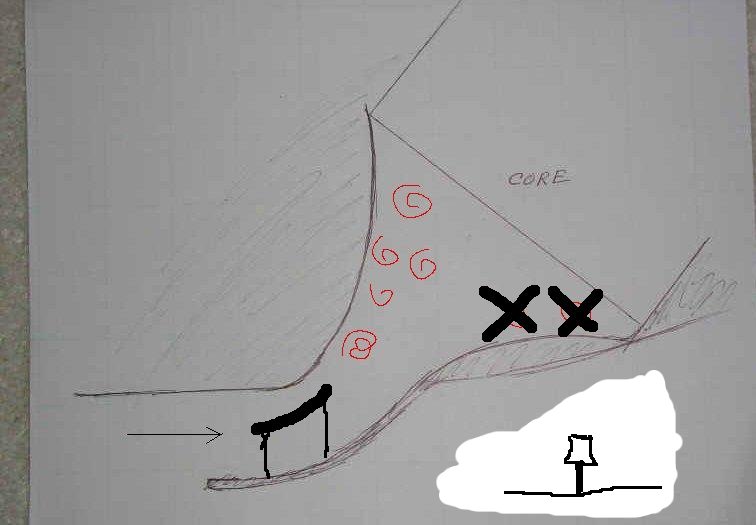

I think there's likely separation as illustrated in the first picture.

I think Paul is right about the wedge diffuser, but I don't think you have

to move the cooler to the cowl. Maybe have a look at the 2nd pic...

What do you think?

Matt-

A simple flap hanging down would be very inefficient. It would force all the dynamic pressure to the rear of the coil, force the air to make a sharp 90 degree turn, and keep all the boundary layer air at the front of the core. The front half of the core would get little to no airflow.

Al, from your sketch, I'm guessing that is the problem you're having now. The front half or your core is sitting idle. Ed mentioned that you're ingesting boundary layer. Weak air. Doesn't have the energy to make a turn. But that is the air that your trying to turn the hardest. I agree with Matt that you will have very stale turbulent air in the upper part of the intake duct, but I'll bet dollars to donuts that the lower section will show very clean flow. The turns are slight, conform to K&W and air is the most energetic in the duct.

I'd concentrate on trying to stir up that boundary layer and try to get some energy into that portion of the duct. Try adding little reverse winglets built on standoffs that you mount to the inside wall of the scoop. If you can ignore my shaky freehand sketching, I've drawn what I would try on top of your drawing.

------------------------------------------------------------------------

Al1.jpg

|

|