|

|

This is only remotely related to rotaries (home of my future rotary-powered RV-4) so please reply off-list.

After having worked for three weekends putting up block and only having done 1 1/2 corners out of 3 so far, I'm seriously considering building forms and having the 9 16x16" columns poured rather that building them up with 16x16" column blocks.

If anybody here on the list are familiar with making concrete forms, I sure could use some advice.

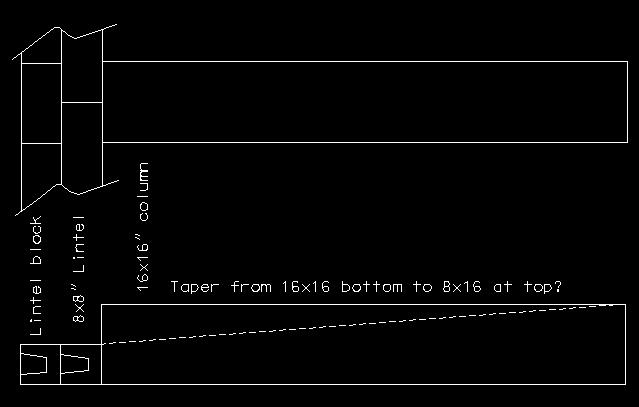

Columns will be 8' 8" tall and will be supporting 10' long 8x8" lintels with a row of lintel blocks on top.

How thick does the plywood have to be to handle a 8'8" tall 16x16" column of concrete?

I'm considering using my future 2x4 or 2x6 frame wall studs to form the outside corners of the forms - two along each corner of the form screwed together (8 per form).

Another issue is the option of tapering the columns: 16x16 at bottom tapering to 8x16" at top. In my mind that would not change the structual strength of the columns; would save concrete (25%) and possibly require less hefty plywood.

I sure could use some advice on both counts.

Keywords here are "cheaper" and "easier".

16x16" column blocks are now $3.21 a piece - 13 per column.

The extra concrete to replace one block is about $2.60 (or $1.95 if tapering the columns).

So I'd mainly just be paying for the plywood for the forms - seems worthwhile compared to the work of "stacking" the 117 column blocks.

Ideally the forms would also be able to support the lintels and lintel blocks so everything could be poured in one go.

Finn

PouredColumns.jpg

NW-corner.jpg

Slab.jpg

|

|