|

|

Leon wrote:

Talk about being "on the case", ... the guy who wrote this is a genius!!! I

confess I couldn't do better myself. ALL the info, ALL the details, and

ALL the diagrams:

See:

http://www.sdsefi.com/air27.htm

http://www.sdsefi.com/tech.html

Enjoy!

Leon,

There is a reason that there are so many types of wheels, not the least of which is that there are so many types of vehicles. The SDS system looks to be designed for multiple tanks and to keep high pressure fuel out of the cockpit. But can't things get so much simpler when you have only one tank that can gravity feed the high pressure pumps, and you allow that 40psi is all that high of a pressure? I think I've done my homework, and will now turn it in for grading.

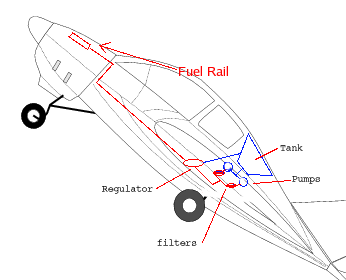

I've attached a improved diagram of what I think would be a good fuel system for a Dyke Delta. Two high pressure pumps under the tank feed into seperate filters (which may need to be switched to before the pumps...there seems to be some counterviews that I haven't sorted through). The line then Ts into a regulator with a single line going firewall forward. A gascolator/drain will have a seperated pickup in the tank that is lower than the feul supply pickup. The beauty in this system is its simplicity.

I've looked reviewed lots of post, taken notice of the cautions and arguments on both sides, and listed my reasoning below.

Problem: The pressure regulator must go after the fuel rail.

Solution: I can not find anything in the way these regulators work to suggest why this would be. The regulator will maintain the set pressure at its intake side by dumping excess fuel out the other side. Like a parallel zener diode, it matters not at which point it is placed on the bus. Nor does it matter how many curves the power or ground circuit have before or after the zener. The voltage will be maintained at the proper level. Likewise, the injectors are T'ed off of the fuel rail, and I'm just adding another T for the fuel rail. Logically, it is the same, even though it's not physically.

Problem: High pressure fuel running under the cockpit.

Solution: I believe it was Tracy that said if there is a cracked fuel line, your nose will tell you long before there is enough fuel to be hazardous. I agree, and will call this acceptable risk in exchange for a simplified system which will be more robust overall (It's guaranteed not to break if it isn't there.)

Problem: Vapor lock

Solution: My understand of the term 'vapor lock' is that the pump is full of air /fumes, and can't generate enough pressure to force anything through. This vapor can be caused by sucking air from the tanks, or heat boiling the gas in the lines. The gas pickup (in a recess in the bottom of the tank), will be covered with fuel untill there is only a cup of so left. The pumps in this case will be 6ft from the firewall, with nothing more than a 1/4" aluminum line to conduct heat. No chance of sucking air as long as I have something to pump, and heat is a non-issue.

Problem: Fuel rail heat soak during flight. Solution: Approach the problem from two ends. Don't let heat get to the fuel, and don't leave much fuel sitting around under the hood.

1)shield the exhaust. 2)provide for blast air around the fuel rail

3)insulate the fuel rail (layer of micro and a couple layups)

4)fabricate a low volume fuel rail from 1/4" tube and a few T-fittings.

With these precautions, I don't see how the fuel could possibly pick up enough heat in flight to be a problem. I would be dependant on how long the fuel remained under the cowl before being used. At full throttle, I estimate around 15gal/hr of fuel used. That equates to .004167gal/sec, or .02672cu.ft/sec. With 1/4" supply lines, and 2ft of line firewall forward, there will be .0006814cubic feet of fuel firewall forward at any time. If I've done my math correctly, there will be 39.2sec for the fuel to pick up heat. I can't get a cup of coffee warm in the microwave that fast, and I'm here we're dealing with an insulated structure that will mostly suffer from radiant heat.

Problem: Hot start. This would be the biggest problem. Park the plane on a hot day, and residual heat in the engine will boil the fuel in the hose that is firewall forward, and push fluid back up through the regulator.

Solution: Hit the cold start button on the EC2. Mixture full rich. If it doesn't crank in a few turns, hit the cold start button on the EC2. (What a hack, using the cold start button for a hot start) The point it to clear out the hot, pressurized fumes. If the engine will run on the fumes, then when it does catch, expect it to run way lean and rough for thirty seconds until the fumes get blown through. There shouldn't be much fumes there. Only the line under the cowl will be heated. As the fuel warms then boils, it will push the rest of the gas back toward the fuel regulator, locking the fumes in to the high part of the system which just also happens to be the hottest (the Delta sits about 9degree nose high on the ground). As the fumes expand and move down the fuel line, it'll eventually reach the firewall penetration. Notice the dogleg in the fuel line on the passenger side of the firewall, from low to high. The fumes will have to push the fuel down the dogleg and all the way back to the fuel tank to cause the pumps to vapor lock, all the while being cooled by the aluminum line. Since trapped gases are a fairly decent insulator and any hot liquid gas would rise to the top, I'd expect they'd only reach an inch or so behind the firewall. A hot start will only be a problem till it uses up the fumes that can occupy the 2ft of 1/4" tube in front of the firewall.

Ding! Ding!

Class is now in session. I have my pen and paper in hand, ready to take notes.

sideview.png

|

|