|

|

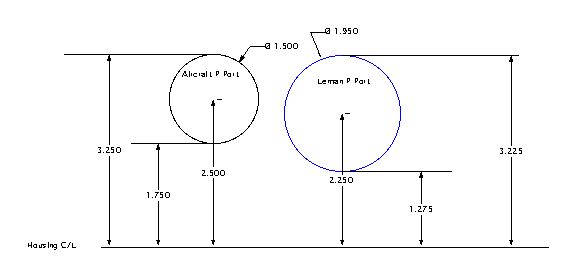

When I was working out the details of my p ports, I made a number of drawings to help visualize what was going on. the one below compares my p port to the Leman P Port which is similar to, but slightly smaller than, the p- port housings sold at this time by Racing Beat.

My p ports open at 78º BTDC and close at 75º ABDC. This drawing shows how much later the ports open in comparison with the Leman P Port and how they close at nearly the same time. According to calculations made by Rolf Peiffer who helped me a lot, my little port has sufficient capacity up to 8000 rpm. After that you would want to go bigger. The exhaust port was left stock with the splitters in. . Jerry

Pfieffer vs LeMan p ports.JPG

On Thursday, January 6, 2005, at 09:03 AM, Russell Duffy wrote:

I see the exhaust closing left stock at around 48 ATDC.

Then open the intake later than stock, to eliminate as much overlap as

possible. The a way late closing point for the intake.

Lynn E. Hanover

This all makes sense, and certainly sounds reasonable. Thanks for being willing to sneak out in the workshop, when I "know" you'd rather be working on house stuff :-)

As for the actual construction, aren't most of these PP inlets just epoxied in place? It just seems hard to believe that it won't leak water at some point if you do that. Is the rotor housing alloy weldable? Can the port be TIG welded inside and out, rather than epoxied?

Should have the RV-3 engine home this weekend, but probably not apart until sometime next week.

Thanks,

Rusty

|

|