Thanks Brent for the photo and discussion. When final assembling the wings the thought of using silicone at the time would have been great. I may or may not have figured that out, but since my IVP has to be considered more of a camel than anything else because I had a couple of build shops involved towards the end, I wasn’t even on site when the wings were last installed. Didn’t have any input at that point.

So now I will live with trying to squirt the RTV into the minimal space around the cuff.

Best regards,

John

From: Lancair Mailing List [mailto:lml@lancaironline.net] On Behalf Of Brent Regan

Sent: Thursday, November 15, 2012 5:43 AM

To: lml@lancaironline.net

Subject: [LML] Re: Pressurization - IVP

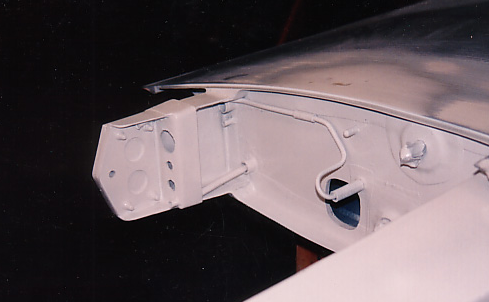

I fabricated a small pressure bulkhead on the aft spar which mated to a slightly conical sleeve. I then used bulkhead fittings for fuel and a CPC connector for electrical. By doing it this way you can use hard line (cheaper, lighter and more reliable than hose) in the wing fairing and it eliminates the need for the lower access hatch. Mate the wing and then connect fuel and electrical on the inside of the cabin. A little RTV on the flange before wing mating seals everything tight. I was able to pressure test my IV-P to 7.5 PSI using a 10Hp air compressor. 1,100 hours later, no problems.

Brent Regan