|

|

If your hydraulic pump is intermittently running then you have a

leak. Period. The amount of air in the system only affects the leak

rate because air leaks faster than oil. If oil is not leaking out of

the system then you have a port to port leak. This type of a leak can

occur anywhere there is an actuator or valve. Before you start

rebuilding system components it may be a good idea to isolate the leak

by capping the lines and monitoring the pressure decay. A ball valve

with a couple of pressure gages "T"ed to each end installed in the line

will allow you to pressurize the system and then close the valve to see

which side of the valve has the leak.

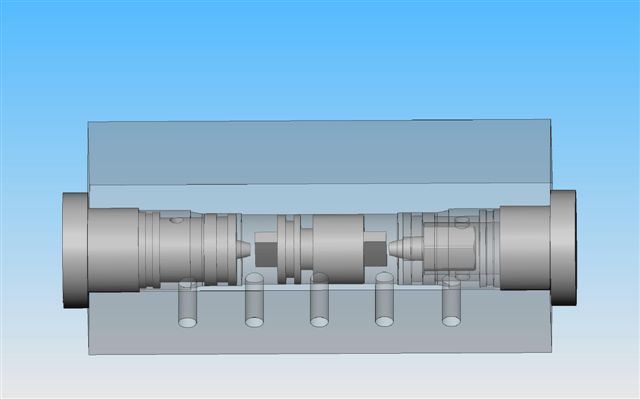

There are four valves (two on each line) inside the pump where a leak

may develop. There are two Over Pressure Relief (OPR) valves and the

two ends of the cross piloted check valve. The internals of the cross

piloted check valve are pictured below.. This valve uses the pressure

side to pilot the return valve open. If the pump is not running the

system is isolated. Contamination is the most common source of damage

to the valve seats.

Randomly changing hydraulic fluid is NOT recommended. MIL-H-5606 is

qualified for use with Buna-N (rubber), the compound most commonly used

for elastomer O-rings. Many ATFs have additives that are incompatible

with some elastomers, Buna-N among them, causing seals to become

brittle or soft. This is why there are "types" of ATF. As the

legendary Mooney story goes, any fluid, even urine, can be used for

hydraulic fluid, for a while. If you are interested in long term

operation, use only qualified fluids.

Regarding airspeed and ground speed, it makes NO sense to do

performance comparisons using a random frame of reference. Sitting at

my desk I have a ground speed of better than 1,000 Kts. Of course, for

my ground reference I have selected a famous stationary landmark. The

Eagle's descent stage.......at Tranquility Base......on the moon.

Regards

Brent Regan

pump valve.jpg

DSCF3146.JPG

DSCF3147.JPG

|

|