|

|

That would have been my next question,

too.

It seems to me that there will always be curves showing

improvement, then decreasing improvement (diminishing returns).

But in the real world, the 'targets' are always moving. Delta-t

between mediums (water-air, oil-air) will change as source temps

change, and as air temps change, so the curves are always moving

in relation to each other. Then there's the issue of aero drag due

to air speed through the heat exchanger, and fluid drag of the

liquid through the HE, and power losses due to both. And even if

we accept some really low airspeed as optimum (ex: 11.2 mph in

that Mocal example), is it reasonable to think we can slow 180 mph

freestream air to 11 mph? And all the above changes with tube size

and fin spacing.

The earlier statement that I can't come to grips with is that the

air can move too fast to absorb the heat. Yes, there's a point of

diminishing returns (where the delta-t gets so small that

efficiency drops), and a point where aero drag gets excessive, but

I can't grasp the idea of the air moving too fast for the heat to

catch it. ;-)

Charlie

On 7/21/2021 10:11 AM, Finn Lassen finn.lassen@verizon.net wrote:

Seems what we're missing is a curve

that's the product of these curves.

In other words some kind of bell or parabolic curve with top

where you have max cooling/drag.

Obviously you can push fluid (and air) through a radiator at a

furious rate, but the drag will go up.

So for both fluid and air rates there must be an optimum spot.

Finn

On 7/21/2021 8:42 AM, Stephen Izett stephen.izett@gmail.com

wrote:

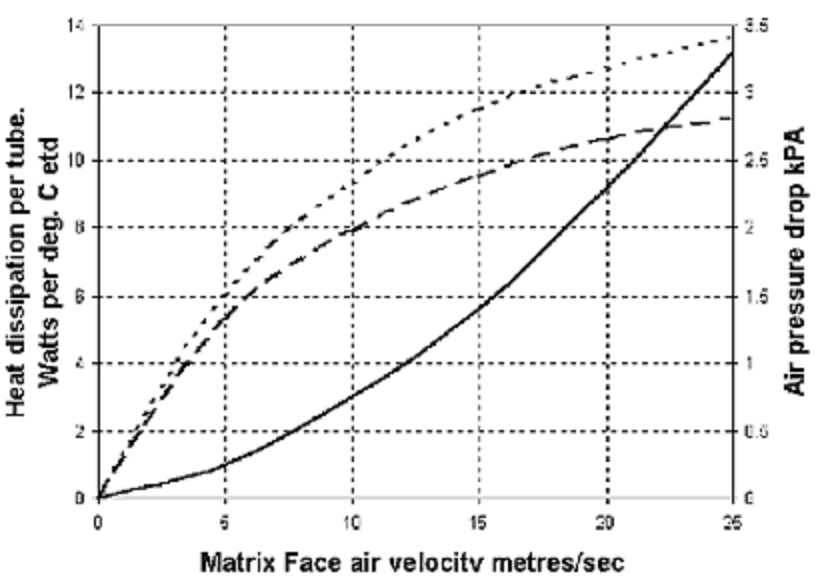

This graph from Mocal might be helpful. It's for their oil

coolers but the trends may be transferable to water exchangers.

The solid line is Pressure Drop.

The two dotted lines tell the story of two

different oil flow rates/tube.

| m/sec |

5 |

10 |

15 |

20 |

25 |

| kmh |

18 |

36 |

54 |

72 |

90 |

| mph |

11.2 |

22.4 |

33.6 |

44.8 |

55.9 |

Increasing the air flow 5 fold from 11 to 56 mph

only increases the heat transfer:

2 fold with an oil flow of 0.02 L/sec/ tube and

2.3 fold by doubling the oil flow rate per tube to 0.04

L/sec/tube

While pressure drop increased 13 fold.

So, diminishing returns from increasing airflow or

fluid flow.

Steve Izett

Charlie,

No, no

reference, just what I have read and also talking

to Rad manufacturers such as BWR in Brisbane. You

can check it out by passing your hand through a

naked flame. Quickly and there is no heat

transfer. Pass slowly and you will see what the

argument is. As I said the truth is there

somewhere and as Lyn so aptly puts it “I could

well be wrong”..

Neil.

Hi

Neil,

Do you have a reference for that? Slowing a medium

down so it has time to absorb the heat seems to

conflict with physics as I've been led to

understand it.

Charlie

On 7/20/2021 5:01 PM, 12348ung@gmail.com wrote:

Charlie,

Much

wisdom out there, you just have to find the

truth! Max cooling is apparently 30 MPH, so

Any faster and it does not pick up heat before

going past. Look at big trucks, that grill is

not only for looks, they slow the air to get max

cooling. If too slow they have a quite large

fan that kicks in to drag air through at 30 MPH

not 100!

As you

say, what do I know – I have seen too many that

do not work – without any degree.

Neil.

Subject: Inlet cooling article

I

remember the Laboda article about enlarging their

cooling inlets, but not many of the details.

This:

The plenum

receives air through two circular air intake

ducts behind the propeller and squeezes it,

Bernoulli-style, so that the air accelerates

across the cylinders and between their fins,

carrying the heat back, down and out an outflow

"gate" at the back and bottom of the engine

area, forward of the firewall.

Is contrary to everything I've ever read about

cooling efficiently. Faster relative flow will

always have higher drag, all else being equal.

Accelerating the air even faster than freestream

just sounds crazy. My understanding is that

there's a balancing act between having the room in

an a/c to 'recover' (increase) differential

pressure across the heat exchanger (engine fins,

in this case), and causing too much drag from the

air going through the fins too fast (there's

aerodynamic drag in the heat exchanger, just like

over the a/c itself). It's surprising to me that

James made the plenum the way he did. The rest

sounds like putting bandaids on stuff. The

next-to-last image, of the final inlet, shows what

appears to be a *much* smaller plenum inlet than

the cowl ring in front of it, and a rather sharp

edged lip where the plenum starts. It looks like

the air would accelerate until it hits that sharp

lip, and immediately go turbulent, which will kill

any pressure recovery and actually slow flow into

the cylinder fins.

Most Lyc plenums I've seen (even the ones James

made for the 4 cyl engines) have significant

volume above the cylinders with smoothly expanding

ducts feeding the plenum. That allows the air to

slow in an organized fashion, which increases

*pressure*, which is what actually makes the air

move through the fins.

But what do I know; I have an Economics degree....

Charlie

Screen Shot 2021-07-21 at 7.58.40 pm.png

|

|