|

|

Bill,

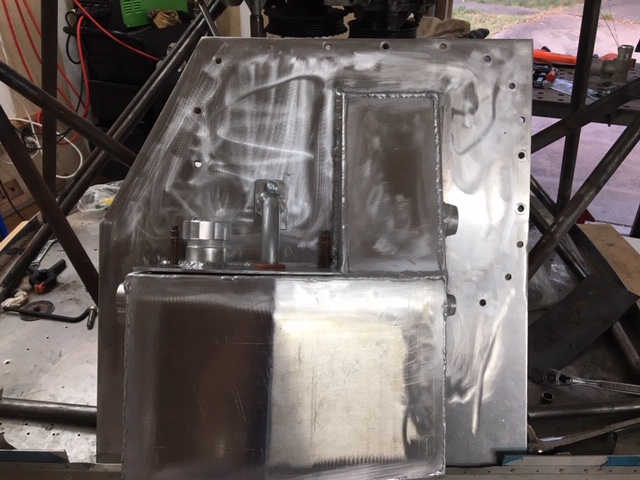

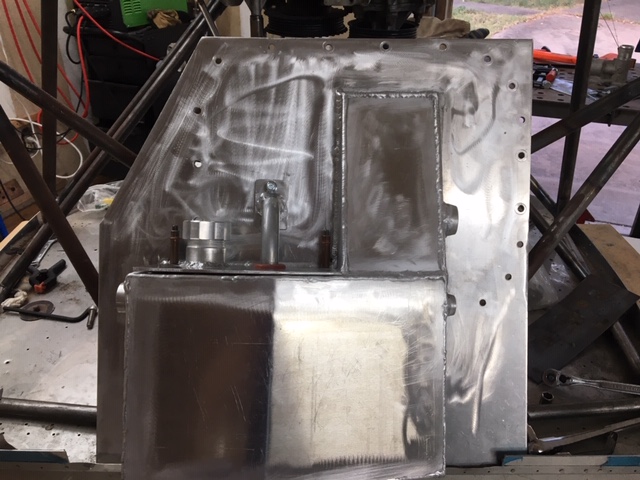

I was under the impression that dry sump systems ended up a heavier installation. My sideways pans trim to size weights 8# and holds about 6 quarts. I may try

to reduce the weight and volume a little. I really like the idea of keeping the oil pickup internal to the pan.

The vertical rectangle box on my pan is open to the oil drain in the center iron with a direct path back to the pan.

From: Rotary motors in aircraft [mailto:flyrotary@lancaironline.net]

Sent: Tuesday, February 02, 2021 3:08 PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: Pluggs Up Sidesump

La Roux, Bobby, and group,

I like your fabrication skills and think the work looks great, That said I have to ask, if you are going to run plugs up, (which is often a good solution in various aircraft), why not go dry sump? If

you are going to fabricate a side sump you obviously have the skills to select and install a dry sump. The nice thing about it is there are many good pumps out there available over the counter. Mazda even had kits for it for the racing guys, until all the

racing organizations banned the rotary because it was an awesome powerplant. There are even several advantages to dry sump. There are many tanks available. LaRoux you might not want to go dry sump now since you have already done a lot of planning and fabrication

for your current set up. But it would be a good idea to get everybody talking about it again. The Superlite engine designed and built by the original PowerSport was both a plugs up engine and dry sump. they even went to the trouble of making one version that

ran backward! This was to get a "correct" prop rotation when running a planetary gear reduction. some of the ex rotary racers can likely tell you where and how many of the dry sump pickups they ran. (How about it Lynn?) The advantage of a separate tank for

oil prevents any uncovering of the oil pickup it is just in the bottom of the tank. There are more lines to plumb and you need a drive pulley for the eshaft but even those can be purchased and adapted from the piston guys. FWIW.

I have modeled the cooling setup used to excellent effect by the Powersport guys. Since even a conventional rotary engine is lighter than a lyc PS made slightly extended motormounts and ran the configuration

shown with great results. Note there are 3 heat exchangers all the same size. Perfect for the rotary since about a third of the cooling is done through the oil. The heat exchangers modeled are 18x18x2" which gives you 648 sq/in of water cooling area or 1296

cu/in if you prefer, and 324 sq/in oil cooling area or 648 cu/in. The inlets can be conventional and they also tried an annular opening which worked fine flying. Conventional inlets did better on the ground though. I just put this together so people could

have a view of a configuration that worked well. H2O Radiators were run in both parallel and series. both work but if you run parallel you need to balance the flow. Both worked okay. (due to message size limit I'm sending the picture separately)

Bobby: Do you have concerns that the oil pick up will run dry with a decent? Not sure what you mean by un-porting the pick up.

If the oilpan has 3 Litres (3,17 USA quarts) in after the system and filters are full then the oil pick up will still be covered with a forward angle of 20 degrees.I have made the oilpan a little bit wider to take more oil as there will

be always be foaming and delays in gravity free flow back to have 3 Litres of “usable” oil always for the pick up.Yes but there is always the difference between the design and what works.Can always put in 1L more oil at weight penalty of more or less 900 g

the “proof is in the pudding” i guess.

Le Roux,

I like the idea of keeping the oil pick up inside the pan. Any concerns with un-porting the oil pickup

in decent? I’m still not happy with mine and may build another one.

Bobby

From: Rotary motors in aircraft [mailto:flyrotary@lancaironline.net]

Sent: Monday, February 01, 2021 12:41 PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Pluggs Up Sidesump

Hi update on my my sidesump.

Just a couple of holes, then its finnished and in place.

Must still weld in the draining plug and dipstick.

Next is the 4130 chrome moly engine frame.

The “dumy firewall” works good to measure everything, and are on wheels to move around in workshop.

Disclaimer

The information contained in this communication from the sender is confidential. It is intended solely for use by the recipient and others authorized to receive it. If you are

not the recipient, you are hereby notified that any disclosure, copying, distribution or taking action in relation of the contents of this information is strictly prohibited and may be unlawful.

This email has been scanned for viruses and malware, and may have been automatically archived by

Mimecast Ltd, an innovator in Software as a Service (SaaS) for business. Providing a

safer and more useful place for your human generated data. Specializing in; Security, archiving and compliance. To find out more

Click Here.

-- --

Homepage: http://www.flyrotary.com/

Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

~WRD000.jpg

image001.jpg

|

|