The calculation is actually fairly simple. Divide the engine weight in

ounces by your hat size, then multiply by

your street address. Convert that number to Cubic Centimeters and

have a friend from Canada look up the answer.

Or, the amount of oil dumped by the regulator varies with RPM, oil pour

weight, oil temperature, oil pump displacement, regulator spring pressure,

suction lift distance, pickup tube end shape, and the shape of the and the

area and hole size of the bug screen selected. Oil pump performance is more

affected by features in the suction side than the pressure side.

Early regulators can be disassembled cleaned and have small washers added

under the spring so as to adjust the cracking pressure to whatever you want. You

oil it up and put shop air pressure in it. Adjust shop air upward to find the

new cracking pressure. It makes a mess and you need eye protection. The twin

turbo relief pressure is 110 pounds. Early ones were 73.9 pounds. Actually test

the one you are about to install.

If you do not know the cracking pressure you cannot make valid judgements

as to oil system performance or trouble shooting.

Mistral said 16 GPM from a test stand at 6000 (engine RPM). Mistral

removed the stock oil pickup tube and made up a nice aluminum tapered piece

(looked like a horn). No bug screen. Defoaming plate had a big screen in the

center to catch debris.

If you have been running a bit hot say 210 degrees. And your usual oil

pressure is 85 pounds but you notice the pressure is now 80 PSI. Power back a

bit and some pressure comes back. Good news. Under hard use throttle position

just about drives oil pressure through a temperature increase. So if you

run it hard and oil pressure drops below cracking pressure, what has most likely

happened? The relief valve is no longer controlling oil pressure. The relief

valve is closed. So, it matters not at all what cracking pressure you wanted.

Temperature can make the pump less efficient. (Bleeds off pressure from the high

side to the low side). Cracking pressure only limits top pressure and has

no other function. Work on the suction side to improve performance.

High oil pressure is used to move overheated oil out of the wedge quickly.

Oils are built for differing functions. I use RedLine 40 weight racing oil.

Not one oil related failure since 1980.

Shifting between 9,400 RPM and 9,600 RPM. About 250 HP These engines use an

external oil pump and hold 100 PSI under all conditions.

We raced for years on 75 PSI oil pressure. You will see a reduction

in pressure as oil temps goes up.

At first the reduction will be from some oil foaming that makes the pump a

bit less efficient. Then the foaming plus thinner oil from temps.

Build a spacer that looks like the pan gasket about 3/8" thick. No

drainback problems.

Lynn E. Hanover

In a message dated 9/2/2016 1:40:36 P.M. Eastern Daylight Time,

flyrotary@lancaironline.net writes:

James,

That’s

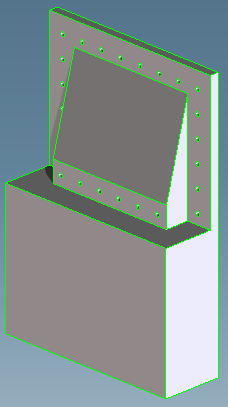

the idea but the relief only needs to cover(uncover?) the midsection of the

center iron and rotor housings. The oil drain back is still through the (7 or

8) 7/8” holes in the plate. Ed used rectangular tube to stand the oil tank off

the plate so the oil pan bolts could be accessed externally. My plate extends

below the engine and forms the inner wall for the oil tank. Mounting screws

are access through the top removal cover. Photo attached but the plate

is covered up.

Bobby

From: Rotary motors in

aircraft [mailto:flyrotary@lancaironline.net]

Sent: Friday, September 02, 2016 11:45 AM

To: Rotary

motors in aircraft

Subject: [FlyRotary] Re: Oil Regulator bypass

Flow Rates

How about something like this Bobby? The challenge

would be figuring out how to do the oil pan bolts along the downward

(intake/exhaust) side of the engine. You would need long bolts and

some kind of standoffs internally to take the boltup forces. Oil pickup

would be internal.

Not to scale, correct oil pan shape or bolt

pattern!

I’m fabricating

a plugs up oil pan and block off plate for my spare Renesis and new turbo

FWF. I’m using Ed’s pictures as a general guide for fabrication. I’m a

little concerned about the oil drain back path and volume. The path

from the center iron and rear iron \ regulator would make most of the oil

flow toward the front iron and down past the oil pump as the bottom of the

rotor housings and center iron are flush with the block off plate. I will

incorporate a recess in the block off plate to provide a more direct drain

path over the rotor housings and center iron humps. The block off plate to

external oil tank drain has (7) 7/8” holes. I’m hoping that’s enough

to keep oil from backing up into the oil pump chain and engine cavity. I am

considering using an external oil pressure regulator installed at a remote

oil filter with bypassed oil feeding directly back to the tank. I know

the 13B oil pumps flow about 15-16 gpm but I have not located any

information regarding how much is bypassed by the regulator. Any

ideas?

RV10

Renesis Super Charged

<Ed Anderson Plugs Up.jpg><IMG_2957.JPG>--

Homepage:

http://www.flyrotary.com/

Archive

and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

--

Homepage:

http://www.flyrotary.com/

Archive and UnSub:

http://mail.lancaironline.net:81/lists/flyrotary/List.html