Hi Al,

Didn’t think I was glossing over

your point (a good one) – as I mentioned in my previous e mail about

returnless systems –

“…

However, these are systems with the pumps generally embed in the fuel tank

– thereby minimizing (if not eliminating) your concern

about the return being “T” back into the line close to the high

pressure pump intake…..”

well, its pretty clear,

that statement didn’t lessen your concern.

You certainly made a valid point about

how important it is to know how close you are operating to a possible failure

point. However, its not quite as easy as implied. In the past I

have used the Clausius_Clapeyron phase change equation to try and get a handle

on crucial temperatures – however, it was simply frustrating without any

useful results - the principal problem I found was the very wide range of boiling

point of gasoline.

Mogas has a range of around 100-400F due

to the various additives put in during different seasons and by different

refineries. Even 100LL aviation gasoline is shown to have a boiling point

range of from 95-330 F

So this makes it difficult to really get

a handle on doing that type of analytical assessment and produce useful results

– and that is for a static system not a dynamic one like we have in real

life where you have heat being added and removed over time.

http://www.engineeringtoolbox.com/fuels-boiling-point-d_936.html

http://www.globalsecurity.org/military/systems/aircraft/systems/engines-fuel.htm

Fuel delivery interruption is not

something you want to encounter under any circumstance. However, to blankly

state (or at least imply) that there is no alternative to a returning fuel to

the fuel tank system , I believe does not provide a complete picture.

Your used the example of millions of

autos in the past having used the “Return to tank” method is not

any different than me countering with the fact that millions of autos today do

NOT use the return to tank system – same level of validity (or invalidity

{:>))

I agree, that in the past that was

certainly the way millions of auto fuel injected systems were designed.

However, millions of autos are now using the “returnless” fuel

system – what would once have been complex and difficult (meaning costly)

to do with a mechanical control system is very amenable to electronic control.

Progress does continue – or else we would all be flying with the same

1932 air cooled designs. . The returnless system has been proven to work

in automobiles so why would it not work in aircraft systems?

A control system design to accommodate a

returnless system similar to that used in many autos today does not appear that

complicated, it would need two control parameters. The pressure in

the fuel line and the temperature of the fuel. So that would entail

adding two transducers to the fuel plumbing. Both fuel pressure and

temperature data then processed by microchip such as I use in my projects could

easily vary the PWM duty cycle to change the pump speed and therefore the fuel

pressure in the line. Not necessarily something your typical builder would

want to take on – not something the majority might want to use - but certain

not beyond the capability of some.

I personally do not think a returnless system is out of the question for aircraft usage – like any fuel delivery system safe requirements would need to be thoroughly understood and carefully designed.

Again, I was not attempting to gloss over your points – I did not find anything in any of your points to challenge – I simply believe your implied assertion that “returning to the tank” was the only way to go because million of autos previously used that system needed to be balanced by recognizing the fact that today - million of newer autos do not use that method any longer.

That said, the returnless approach may not turn out to be suitable for our use for some reason, but I don’t see any reason - at this point- why it should be discounted out of hand.

In fact, this discussion has intrigued me to the point, I am going to look into what it would take to add such a pressure management system to my current system. My small header tank (1 pint) already has fittings welded in that would make it easy to install a pressure and Temperature sensors. I am not concerned about vapor lock in the high pressure part of my system – but the low pressure part is obviously where elevator temperatures would have an easier time of causing fuel vapors to manifest themselves.

Everyone on this list ultimately makes up their own mind about what information to use and how to evaluate it, all view points are welcome on this list – that is why it exists. There is no moderator to make those judgment calls about what should or should not be discussed or mentioned – it’s up to everyone to take the input provided and make their own decision about it. That’s why this list is great!

Onward indeed!! {:>)

Ed

From: Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On

Behalf Of Al Wick

Sent: Tuesday, June 08, 2010 10:59

AM

To: Rotary

motors in aircraft

Subject: [FlyRotary] Re: high/low

pressure pumps question

Hi Ed. You often make significant contributions that help

improve flight safety. If you share your fuel design, at least do the

calculations and let users know how close this is to vapor lock. We're talking

about life risk here. You are glossing over my point and changing the topic.

Returning fuel to pump inlet is very risky and should not be done unless you

desire to operate on the threshold of vapor lock.

I agree, there is one exception. That's if you have one

of the new fuel pump controllers that measures fuel parameters and alters pump

speed. I looked into that one years ago. Talk about added complexity!

----- Original Message -----

Sent: Monday, June 07,

2010 8:00 AM

Subject: [FlyRotary] Re:

high/low pressure pumps question

Points noted, Al.

However, would like to point out that

today many automotive fuel systems DO NOT return fuel to the tanks – they

use the “No-Return” fuel systems whereby pump pressure is

regulated to prevent vapor lock. However, these are systems with the pumps

generally embed in the fuel tank – thereby minimizing (if not

eliminating) your concern about the return being “T” back into the

line close to the high pressure pump intake. With millions of autos now

using this system – it would appear to be a viable approach if done

correctly (always the caveat {:>))

That is one point that Charlie made - was

the possibility of using a simple PWM circuit to control pump pressure similar

to the no-return Auto systems.

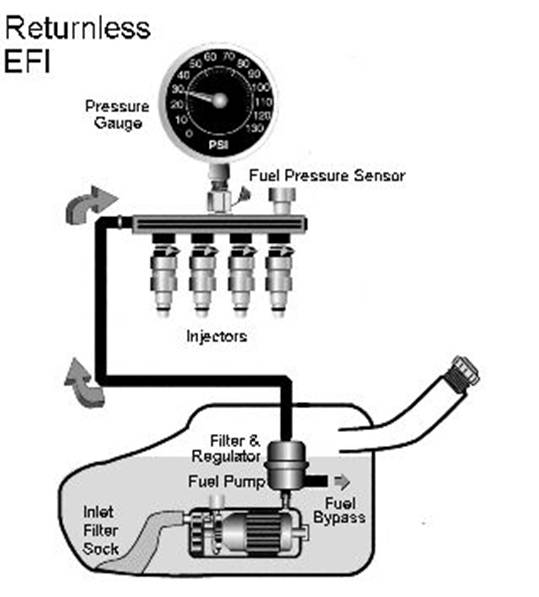

For those interested, here is a fairly

good non-technical description of a no-return system used in automobiles.

Ed

http://www.picoauto.com/tutorials/fuel-injection.html

Returnless Fuel Systems

Have been adopted by several motor

manufacturers and differ from the conventional by having a delivery pipe only to the

fuel rail with no return flow back to the tank.

The returnless systems, both the mechanical

and the electronic versions, were necessitated by emissions laws. The absence

of heated petrol returning to the fuel tank reduces the amount of evaporative

emissions, while the fuel lines are kept short, thus reducing build costs.

Mechanical Returnless Fuel Systems

The ‘returnless’ system differs

from the norm by having the pressure regulator inside the fuel tank. When the

fuel pump is activated, fuel flows into the system until the required pressure

is obtained; at this point ‘excess’ fuel is bled past the pressure

regulator and back into the tank.

The ‘flow and return’ system has a

vacuum supply to the pressure regulator: this enables the fuel pressure to be

increased whenever the manifold vacuum drops, providing fuel enrichment under

acceleration.

The ‘returnless’ system has no

mechanical compensation affecting the fuel pressure, which remains at a higher

than usual 44 to 50 psi. By increasing the delivery pressure, the ECM

(Electronic Control Module) can alter the injection pulse width to give the

precise delivery, regardless of the engine load and without fuel pressure

compensation.

Electronic Returnless Fuel Systems

This version has all the required components

fitted within the one unit of the submersible fuel pump. It contains a small

particle filter (in addition to the strainer), pump, electronic pressure

regulator, fuel level sensor and a sound isolation system. The electronic

pressure regulator allows the pressure to be increased under acceleration

conditions, and the pump’s output can be adjusted to suit the engine's

fuel demand. This prolongs the pump’s life as it is no longer providing a

larger than required output delivery.

The Electronic Control Module (ECM) supplies

the required pressure information, while the fuel pump’s output signal is

supplied in the form of a digital squarewave. Altering the

squarewave’s duty cycle affects the pump’s delivery output.

To compensate for the changing viscosity of

the fuel with changing fuel temperature, a fuel rail temperature sensor is

installed. A pulsation damper may also be fitted ahead of or inside the fuel

rail.

Here is one rendition of such a system in an auto

application

Ed Anderson

Rv-6A N494BW Rotary Powered

Matthews, NC

eanderson@carolina.rr.com

http://www.andersonee.com

http://www.dmack.net/mazda/index.html

http://www.flyrotary.com/

http://members.cox.net/rogersda/rotary/configs.htm#N494BW

http://www.rotaryaviation.com/Rotorhead%20Truth.htm

From: Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On

Behalf Of Al Wick

Sent: Monday, June 07, 2010 9:25

AM

To: Rotary

motors in aircraft

Subject: [FlyRotary] Re: high/low

pressure pumps question

I'm really concerned for your life risk. This is a very high

risk fuel design. Puts your fuel pressure at pump inlet very very close to the

vapor pressure of fuel. This suddenly makes the design sensitive to a whole

bunch of environmental factors.

Ask this question: Millions of automobiles. When they

designed automotive fuel systems, why did every single engineer return fuel to

tank instead of pump inlet? So much more expensive to send to tank.

You can bench test your design and prove how close it is to

failure. Just need to measure fuel pressure at pump inlet, measure pump temp.

Use hair dryer to force pump to higher temp. Put all the numbers in

spreadsheet, then calculate distance between vapor pressure and your readings.

Adjust for worst case, which would be high altitude airport, hot day sitting on

tarmac for 1 hour, heat soaked engine compartment, car fuel containing ethanol.

Marginal designs can fly for years without failure. This is

the nature of failure. Use care, I'm concerned.

----- Original Message -----

Sent: Sunday, June 06,

2010 6:47 AM

Subject: [FlyRotary] Re:

high/low pressure pumps question

Hope this helps...

On 6/6/2010 2:21 AM, Todd Bartrim wrote:

>

> Hi Charlie;

> Hmmmnn, I gotta say a picture (or drawing) is worth a thousand words.

> Todd (sent on my new-fangled google phone with a really damn small

> keyboard)

>

>> On 2010-06-05 8:46 PM, "Charlie England" <ceengland@bellsouth.net

>> <mailto:ceengland@bellsouth.net>>

wrote:

>>

>> Hi Todd,

>>

>> My thought is to set up the fuel path thus: fuel source through a T

>> into injection pumps, through filters, through combining T, through

>> the regulator(in cockpit), through firewall to engine. The

>> regulator's bypass port (in the cockpit) would be plumbed just like

>> yours, except no heat exchanger since the bypass fuel would never see

>> the heat of the engine compartment. The bypass would still T into the

>> supply to the injection pumps, like your system. Obviously, a

>> manifold pressure line would be required through the firewall into

>> the cockpit to the pressure regulator.

>>

>> My original plan (different injection that didn't require a return

>> line) was similar to your selector setup: main tanks feeding stock

>> van's selector, with the 3rd port on it being fed by a 2nd vans

>> selector to select either of the 2 aux tanks. No transfer pump would

>> have been required, & no crossover valve. Failure of the primary

>> valve could have been a 'show stopper', but the newer valves seem to

>> be rock solid reliable. Going to this system using the gear type

>> pumps requiring a return line forced re-thinking. Using your idea to

>> return the bypassed fuel at the pump inlet effectively eliminates the

>> 'return' issue, & tempts me to return to the original fuel

selector

>> layout, with the addition of a Facet boost pump. The fact that the

>> optical sensors will work looking into the side of a fuel line (the

>> T), instead of needing them in the tank & that they still give

almost

>> a full minute's warning, is very encouraging. I'll start looking for

>> a convenient place to mount them.

>>

>> I hope that Tracy

will chime in on how he plumbed the regulator on

>> his -8.

>>

>> Many thanks for the extra details.

>>

>> Charlie

>>

>>

>>

>> On 6/5/2010 12:32 PM, Todd Bartrim wrote:

>>

>> >

>> > Hi Charlie

>> > Not sure I understand

correctly what you mean? Can you

>> sketch it out quickly? I'...

>>

>> > *From*: Charlie England <ceengland@bellsouth.net

>> <mailto:ceengland@bellsouth.net>

>> <mailto:Charlie%20England%20%3cceengland@bellsout.

>> <mailto:Charlie%2520England%2520%253cceengland@bellsout.>..

>>

>> > *Subject*: [FlyRotary] Re: high/low

pressure pumps question

>> > *Date*: Sat, 05 Jun 2010 08:38:09 -0...

>>

>>

>>

>> --

>> Homepage: http://www.flyrotary.com/

>> Archive and UnSub: http://mail.lancaironline.net:81/lists...

>>

--

Homepage: http://www.flyrotary.com/

Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html