|

|

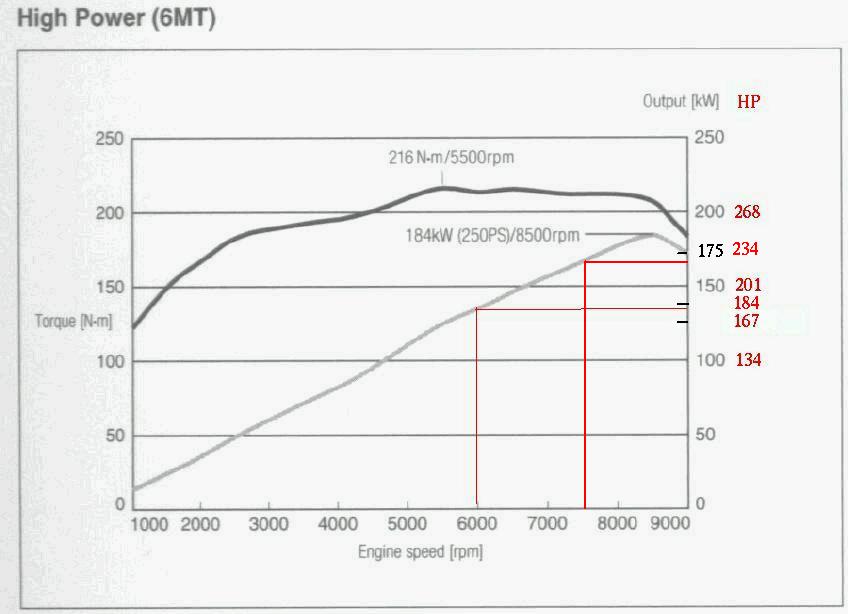

The prop absorbs HP proportional to the cube of RPM. That is a mighty steep curve. If you built a prop to absorb 243 HP at 9000 engine RPM, it would take just 63 HP to twist that same prop at 5700 RPM. (The torque required follows a square law, by the way.)

The torque curve of the six port (with the stock manifold) is pretty flat. Take a look at the attached file.

With no valves in the manifold, the torque below 5000 should drop off much more sharply, but the prop will just be a flywheel with a little wind drag.

I plan to run the engine against my planned "Artesian" disc brake dyno to find out what the curves look like with a no-valve manifold. If the torque curve is completely unacceptable, it is not an extreme modification to make the secondary valves operate at low throttle settings (instead of leaving them fixed wide open.) I don't think this will be needed, however.

Bill Dube'

Ernest Christley wrote:

BillDube@killacycle.com wrote:

In the car, all the intake valves are open at something like 6500 RPM (maybe even lower.) My manifold emulates the stock manifold in this condition. Should work OK for the expected RPM operating range.

With a 2:85 PSRU, the max prop RPM will be 3157. As I understand it, this should not be a problem for a 72 inch prop. You just have to pitch it correctly to absorb 243 HP at that RPM (at altitude.)

Bill, I think Ed was saying that if you pitch the prop to absorb 243HP at 3157, then it will be producing ?160HP? at ?2000RPM?. You're engine will be turning 5700 with the prop at that RPM. The question is, "Will 5700 engine RPM produce 160HP or greater?" If you don't get >160HP at 5700 RPM, you'll never be able to get TO the 243HP that is sitting there waiting for you. A CSprop would let you feather it past the lower RPMs and bring you into the sweet nirvana where you manifolds tuning works at its maximum. With a fixed pitch prop, it may be questionable until you build one and try to run it.

How'd I do, Ed?

RX8-HP-curve.jpg

|

|