|

|

>

> [||B||]---------(C)--(C)-----------(S)-(M)

>

> Don't you actually have three "contactors" above: the solonoid is also a contactor. Surely if two didn't work going to a third is not worth it. As I see it the solonoid has a short that provides power from voltage to its' contactor terminals to it's winding terminal. Since my second contactor is in parallel with the solonoid windings this short activates it as well. The probelm is resolved by not using the contactor terminals on the solonoid but just using it to through the gear in. Power from the first contactor goes to motor.

>

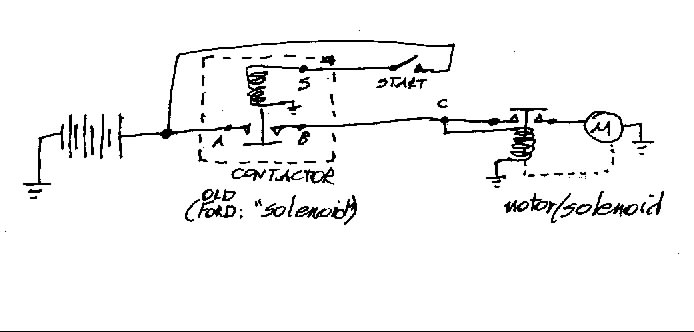

I've attached a quick freehand drawing, showing what I suspect is your current circuit. Sorry about the free-hand.

If you press the "start" switch, current flows through point "S" and the contactor closes, making current available from point "A" to point "B" and, thereby, the solenoid. At that point nothing should have happened except the "click" of the contactor. Now, depending on how the solenoid is supposed to be activated, the same "start" signal may be routed in parallel to the solenoid coil without the connection at point "C"; this would energize the solenoid only as long as the "start" switch was closed. In the circuit in the drawing, a common cost-saver is to connect the solenoid to the high-current cable such that it will stay energized as long as there is voltage at point "B". The idea is that

when "start" is opened, the contactor will de-energize and remove voltage from point "B", removing both the current source to the motor AND the energize power from the solenoid. If the contactor should fail *closed*, then the motor keeps running.

Thus, removing the "start" wire from the contactor should

leave ~0 volts at point "B". If you can still see ~12V at point "B", then the contactor is stuck closed.

Disconnecting the solenoid coil connection from point "C" and running it to point "S" will give the same effect as having two contactors in series - but it may be hard on your switch, as the solenoid may pull a lot of current to make the gear engagement. That could be resolved by adding a relay to provide current to the solenoid coil. However, that connection may be made *inside* the solenoid housing, and not be easily re-routable.

Dale

startcir.jpg

|

|