|

|

Gary,

Attached are the drawings in jpeg. If you still have questions, let me

know.

John

Gary Casey ha scritto:

John,

I'm afraid I don't quite understand your description of the

proposed fix. Possibly the mounting system is enough different from my

ES and I couldn't find the attached drawings. In any event would you

be kind enough to elaborate. The subject is certainly of interest to

everybody, especially those with an ES or IV. I gather that you

Columbia mounting is such that the complete strut had lateral play and

I can see that such a thing would be very bad in almost any amount. In

fact, I would guess that either kind of play is bad - lateral or

rotational. I've never had a trace of shimmy in my ES, but I don't

know why, and that worries me.

Gary

ES #157, strut rebuilt by Lancair, 170 hours and 3 years ago.

-----Inline Message Follows-----

I have read with interest the thread on nose wheel shimmy since, though

I am building a IV-P, I am currently flying a Columbia 300, and have

been plagued with increasingly severe nose wheel shimmy.

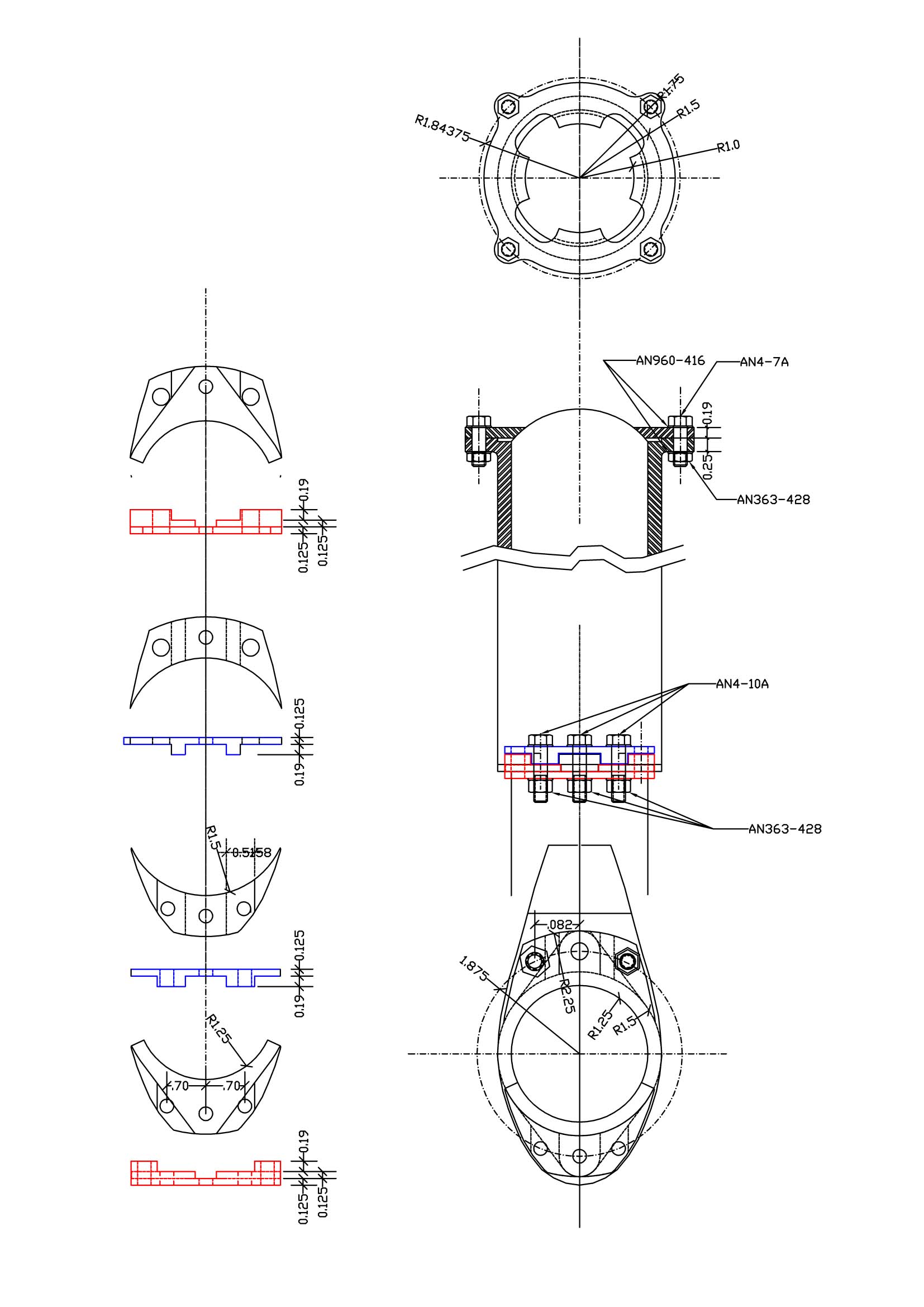

At my last annual a strengthener was added on the front tab to

compensate for the enlargement of the holes in the mounting tabs (photo

1). Obviously the intent was prevent rotation around the axis of the

strut. Result: one landing with minor shimmy, but increasing violence

with each subsequent one. Also there was shimmy during take off. So I

decided to balance the the nose wheel - it hadn't been done before.

While remounting the nose wheel I found that there was lateral play of

..270" in the nose strut (photo 2). I decided not to fly the plane

again until corrective action had been taken. And this was before the

photo of N166DS was posted.

Looking at the configuration of the nose strut on the Columbia, which I

assume is the same as on the ES - why else would I post this to the

Lancair List - the problem is obvious. The nose strut is fastened to

the engine mount by two AN4 bolts in the longitudinal axis. If the

tube on the engine mount were a close fit to the nose strut, the two

bolts might be sufficient. But since it isn't, they are wildly

inadequate. The result is that there is twisting moment the mounting

that

leads to the enlargement of the mounting holes. In the lateral axis

there is no support at all.

What to do. I have proposed the solution shown in the two attached

drawings to Cessna, and have a DAR who sign off if Cessna has no

technical objections. Cessna promised a response within 7 to 10

working days on 4 August, but as of today I still don't have a

response. Upon asking why, I was told they are working on a service

bulletin. Not wanting to do something irreversible, but wanting to fly

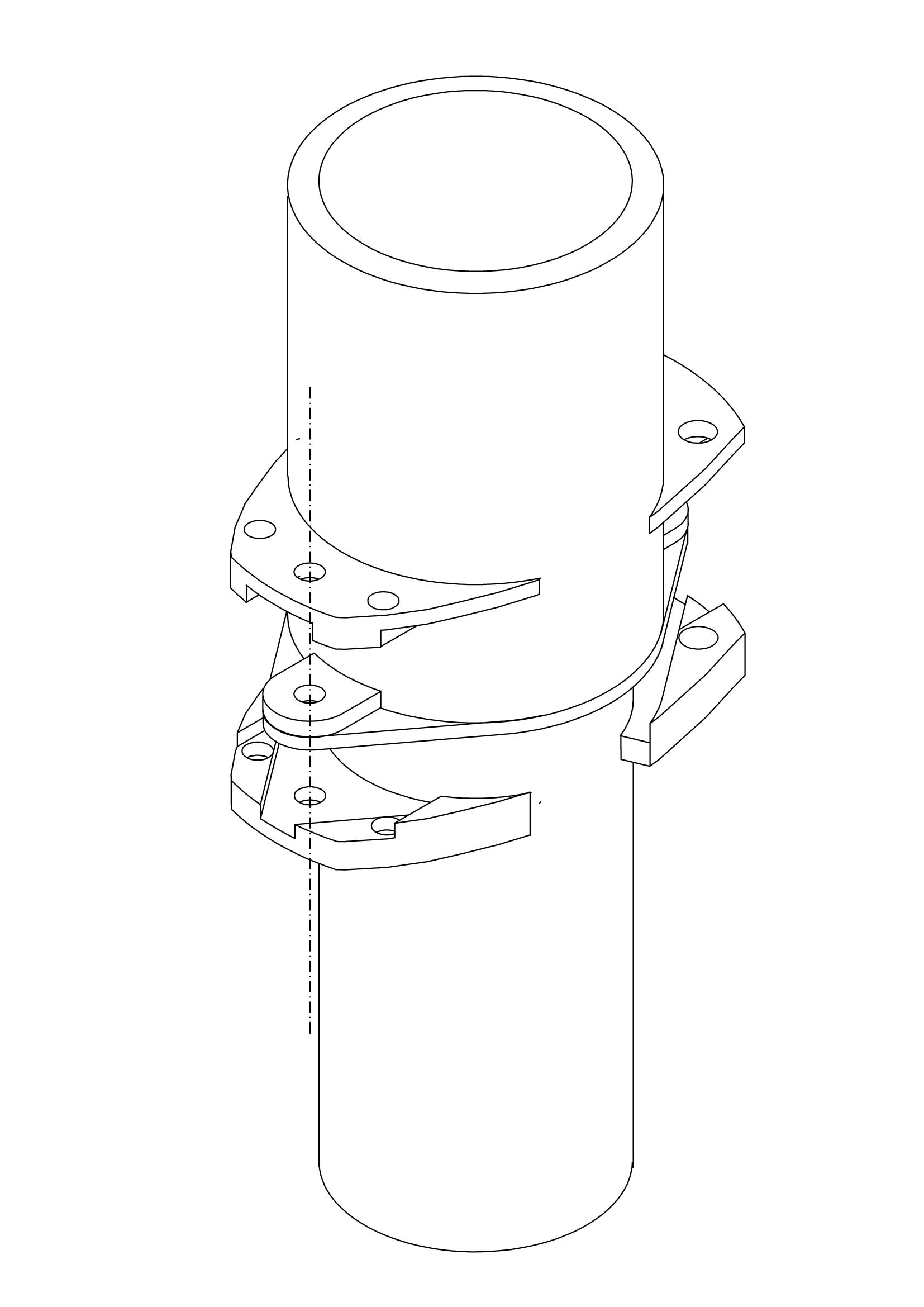

the plane, I made the re-inforcing parts shown in the isometric

drawing, and installed them without welding them to the engine mount

and strut. In eight take-offs and landings since I have not had any

shimmy. Welding the parts would probably make it bullet proof.

A few notes on the parts. The intent of the design is not only to

eliminate the play in the lateral axis and the rotation of the strut,

but also to remove shear loads from the bolts. On the rear brackets

the outboard bolts are AN5. If I were building an ES, I would remove

the tabs as delivered, and eliminate the center bolt which serves no

purpose.

Hope this is useful.

John Herminghaus

LIV-P I-VVVV

nose strut3i copy.jpg

nose strut3 copy.jpg

|

|