|

When I modified my 235

to an IO320 engine in 1968, I added a horizontal rib to stiffen the

tail. It is

wedge shaped about 2 feet long and sits at the height of the stabilizer and

butts against the little bulkhead back there. There is a natural "ledge" on each side

where the vertical fin

attaches to the fuselage. The rib is shaped to

fit this ledge and anchored with hysol and 3bid tapes top and

bottom.

This was done on the advice of Ray Modert who made this

modification after one of his friends reported some serious "buzz" in the tail

at 220 mph. The rib is 1/2" plywood with 3 bid on each side. Sitting on the rib

is a 12 lb chunk of lead, which balances the extra 40 lb. of engine and

propeller weight. I think I'm still a little nose heavy, but not enough to cause

any problem bringing the nose up to flare at 75 kts. My new empty weight is

1035, up from 970.

If you apply a torsional load to the tail section by

pushing down on one end of the

stabilizer, you can see that it is not real stiff, torsionally. A whack on the vertical fin or

stabilizer would produce a noticeable vibration.

I made a crude

measurement of before and after torsional strength by putting a lead brick

on the outer end of the stabilizer and measuring the deflection. .

I have attached a note which describes the

test

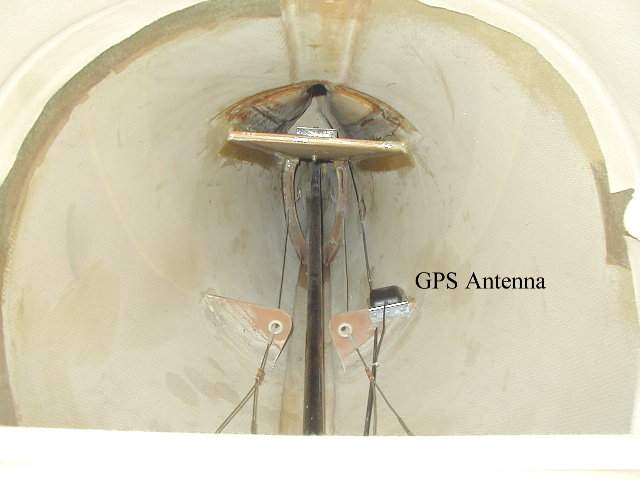

The rib installed, looking back into the

tail. This was all done from the inside, with difficulty.

I made some bid tapes which go down each side,

top and bottom. You can see the lead weight

sitting on top of the rib back there.

|

|

|

|

|

|

|

|

|

Here is a picture of the

rib before installation. It is 1/2" marine plywood with 3 BID

on each side.

I made a piece of

foam with bondo on the edges which I pushed back there to determine the

shape.

|

|

|

|

|

|

3 of 3:

C:\Pictures\Flight\N19BJ\Airframe\theRib.jpg

|

| |

ATT00079.jpg

ATT00085.jpg

|