|

|

Most kids like to take things apart. The ones that learned to reliably reverse the process usually go on to become engineers.

I first learned about these fasteners over 30 years ago when I was designing and building IMSA race cars. I was visiting another car builder, Dave Kent, in Los Angeles and he took me to an aerospace fastener surplus store where you could buy "sweepings" from the various aerospace facilities. You could get every kind of cool high performance fastener and pay by the pound! If I knew then what I know now I would have mortgaged the farm and bought the entire store. A couple of years later there was a scandal where where people were buying up these surplus parts, repackaging them and selling them back to the market as new. The FAA cracked down and my "Fastener Heaven" store vaporized and is now a tattoo parlor. BTW, it was Dave that introduced me to WLS coatings. Dave also had a penchant for topless bars and double Dewer's up, but that is way off topic.

Tridair fasteners are positive retention fasteners, originally designed for supersonic aircraft. Dzus and Camlock fasteners are "fixed force" spring type. When you use a spring fastener you produce a fixed clamping force at the fastening interface. This is bad news in high vibration environments as the vibration can momentarily separate the two clamped parts, allowing them to move laterally and cause fretting and wear. If you examine most spring fastener installations that have been in service for a while you will see indicia of wear proximal to the fastener.

The Tridair fasteners are different because there is no mushy spring in the clamping system. Also the OD of the female "screw" is a close tolerance fit to the ID of the receiver. This provides positive clamping without the wiggle.

HOW THEY WORK

There is a reason these things are expensive.

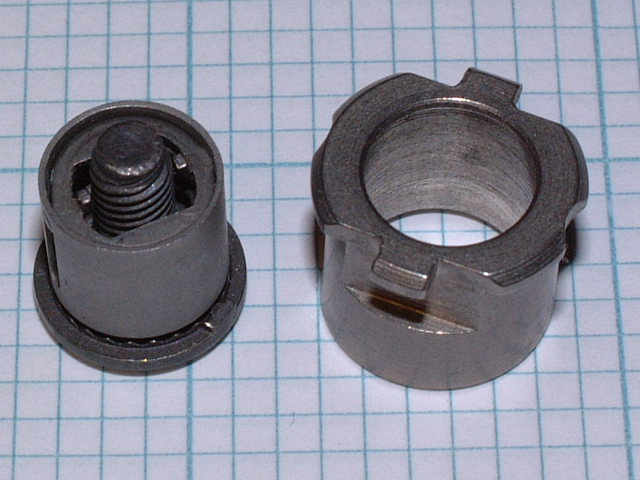

Refer to the pictures below. All the magic is in the receptacle. The housing is capped by a stud that has a multi start male thread. Inside the housing is a coaxial barrel that contains a spring that prelaods an axial sliding plate. On the bottom of the barrel and the top of the stud heads are radial teeth that engage each other.

During assembly, slots on the end of the screw engage tabs on the sliding plate. Other tabs on the perimeter of the sliding plate engage slots in the barrel so that as the screw turns the sliding plate the plate turns the barrel, causing the teeth to on the barrel to rotate against the teeth on the stud. This produces a clicking noise during assembly and removal. It also prevents the fastener from loosening in service.

Installation and use tips:

Try to only use one grip length. I used -2s. This eliminates the possibility of using a wrong length. You can grind down or bid up the receiver mounting area to make the grip distance within the fastener's range.

The retainer clip is not a requirement. Having the screws come off of the cowling eliminated the possibility of having them scratch the paint during reassemble.

Use a reamer (0.251") to size the holes with the cowling mated to the fuselage. Repeat after painting and then install the receivers.

Periodically wash out the screws and receivers and relubricate with something better than WD40 (e.g. LPS #2 spray lubricant).

Remember, paying for quality is a tough decision to make but an easy decision to live with.

Regards

Brent Regan

DSCF4037.JPG

DSCF4038.JPG

DSCF4036.JPG

|

|