|

|

2003 Flight

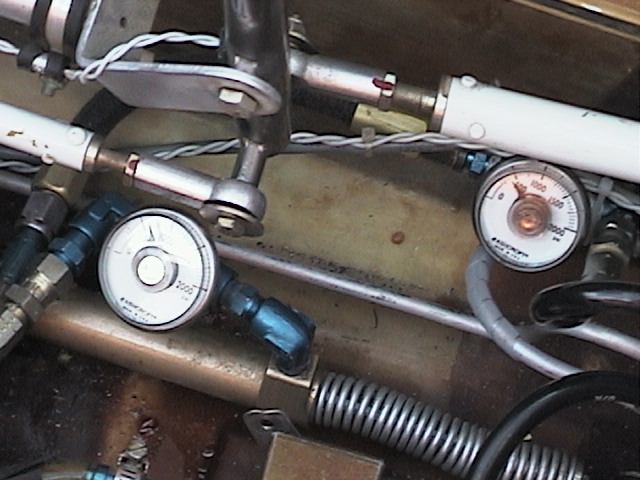

Attached are 2 photos taken after a 3 hour cold high altitude flight. The pump chirped 3 times or once per hour over the course of the flight. The pump ran for about 1/3 of a second each time. The gear lever was put down at the outer marker but the pump didn't run. I didn't notice because of an 80 knot crosswind at 500 ft with 8 knots on the ASOS.

I have learned since that a quick pull and push of the dump valve would have corrected the problem.

Notice that the low pressure (left) pump is reading about 700 lbs. This pressure was developed in flight during the 3 pump burps. My spool valve is installed correctly.

The spool valve should have allowed the leak from the high pressure side to flow out of the low pressure side through the spool valve to the reservoir. It did not. As Chris Z. mentioned, I can almost always predict when this problem will occur and plan on opening my dump valve momentarily. The problem occurs about every 20th flight, always after a long cold high altitude flight. I don't know why the spool valve does not allow the low pressure side to decompress in cold weather at high altitudes, but it does not.

The above statements, based on my experience and gauge readings, are what I believe causes some of our gear down problems.

Lorn

AUT_0310_2.jpg

AUT_0316_2.jpg

--

Lorn H. 'Feathers' Olsen, MAA, DynaComm, Corp.

248-345-0500, mailto:lorn@dynacomm.ws

LNC2, FB90/92, O-320-D1F, 1,300 hrs, N31161, Y47, SE Michigan

|

|