I was pondering the ES nose wheel shimmy issue while

walking the dog, and it occurs that we have enough information and smarts in

the LML community to put this one to bed. It is just to persistent not to

warrant a full court press.

Disclosure: I am finishing a Lancair IV, and so can

comment only as an “outsider.”

Below I offer some basic insight into vibration,

speculate on causes, and offer some suggestions, but they are all based on the anecdotal

reports of LML, some work in shock/vibration many years ago, and a course in

vibration theory in engineering school during the Paleocene. With that in

mind….

Some Basics

Shimmy is vibration, and shimmy suggests vibration at

or near the natural frequency (resonance) of an oscillator which is somehow

excited to do its thing: oscillate at its preferred frequency.

Mechanical oscillators usually trade energy between a

spring (anything that can store energy as a function of deflection) and the

kinetic energy of motion in which the spring energy is traded for moving a mass.

You need a spring to store energy (it can be a beam, strut, engine mount or some

other bendable structure), a mass to wiggle, and an excitation force to start

the wiggle. When the frequency of the exciting force equals the natural

frequency then – bingo! - you have resonance and lots of big wiggles –

IF the oscillator is not adequately dampened by friction.

The excitation force can come from within the mass (a

vibrating engine), from the outside world applied to the mass (a gust bending

your wing) or from through the spring from the “base” moving up and

down such as a speed bump thumping your car through the suspension. The

responses are all roughly the same for purposes of this discussion – when

excitation force equals natural frequency, you get resonance - so we will

use the simplest model.

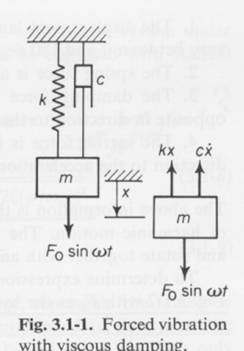

An example is shown below, copied from my old theory

of vibrations text book.

Here we have a base anchor point (top), a spring and a mass with a damper

in parallel with the spring. The weight wiggles up and down, and in this example

the excitation force is applied to the weight. The spring can be a torsion

spring and the weight can rotate back and forth, but the behaviour is essentially

the same.

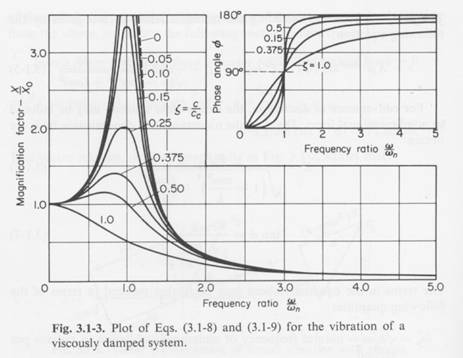

Here is how movement of the weight responds to the excitation force as you

vary its frequency. Ignore the top right chart which shows phase angle, and

focus on the larger chart showing the magnification factor. Frequency is on

the bottom axis and the magnification factor of the weight movement is shown on

the vertical axis. The different curves show different levels of dampening.

Omega sub n is the natural frequency of the system. It is defined by the

stiffness of the spring and value of the mass.

First message: the greater the dampening, the lower

the magnification factor. When the excitation frequency is right on

the natural frequency, we call it resonance. If the dampening is low and

resonance occurs for a very long period (which can be millions of cycles for a

crankshaft or less than a second for wing flutter) the structure can

fail.

So dampening is good for minimizing vibration at

resonance.

Staying away from the natural frequency is good, but

for us, not possible. Since we are landing at (say) 80 knots and slowing

to zero, the excitation frequency, if it comes from tires, covers a broad range

down to zero. It is hard to change the natural frequency (goes as the

square root of spring constant over mass) so it is better to zip through the

natural frequency quickly to prevent the vibrations from building up.

Complications

The key factors are the mass, the stiffness of the

spring, the amount of dampening, and the frequency and amplitude of the exciting

force. The complication arises in from the fact that we do not have a

simple spring mass system. Rather we have somewhat flexible strut mounted

on a less flexible engine mount which is mounted on a big mass (the airframe)

which is not really a fixed base like the foundation of a building, and can be

wiggled as well. Also, the excitation can come from multiple sources from

outside the wheel/strut assembly (main gear brake wiggles which push the nose

wheel from side to side) or from within the wheel/strut (nose wheel imbalance

and from the self-centering forces arising from the caster angle of the strut).

More complication: the self-centering force arising

from the caster angle is like a spring. It applies a restoring force that

tries to push the nose gear to an equilibrium position. The restoring

force from the caster angle can be BOTH like a spring (restoring force gets

larger as the wheel turns more) and an excitation force since the tire

interacts with the ground and can collect energy from the ground/tire forces

when things start to wiggle. And the tire patch also offers some

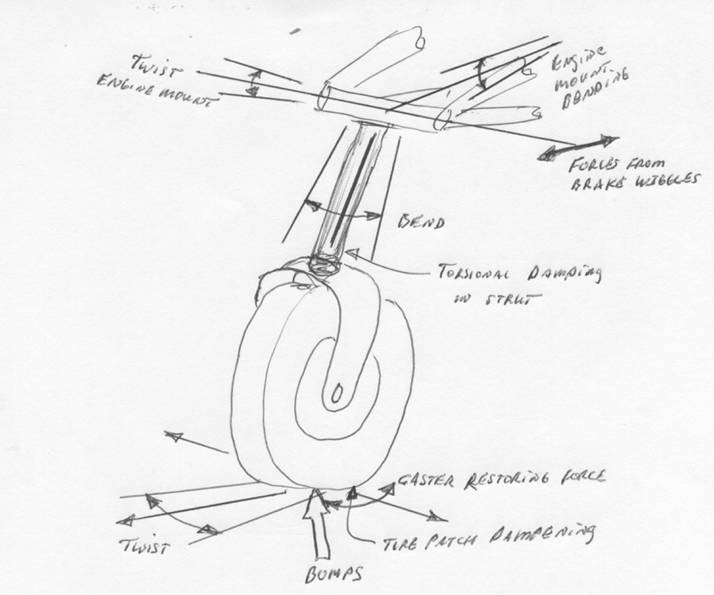

dampening. The picture below gives an inkling of the complications.

(Please forgive my artwork.)

Clearly we have lots of springs, forces, and masses

(including torsion springs and masses) in the system. Add the fact that

portions of the airframe like to wiggle, and it gets even more difficult to

analyze. But understanding the simple model is enough to help diagnose

the problem. Excitation forces, springs, masses, and dampening are the

keys. Let’s review each in turn.

Springs and Masses

Not much we can do here. Basically we would

like to adjust the natural frequency of the strut assembly to be so high (or so

low) that real world excitation forces will not cause resonance to begin.

Fuggedaboutit. You can not change the spring stiffness or masses enough

to make a difference.

With three exceptions: ES aircraft have a nose wheel

pant which increases the torsional moment of inertia which reduces the

rotational natural frequency of the nose gear compared to no nose pant. Moving

the frequency down lower may make the torsional natural frequency come closer

to the strut bending natural frequency. If they lay on top of one

another, you are more likely to get trouble. But I speculate, and the

reports suggest other causes are more likely.

The second exception is the length of the

strut. Extended, it is more flexible (lower natural frequency) than when

retracted. On my 182 RG the rare nose wheel shimmy could be stopped by

pushing the stick and shortening the strut. That raises the natural

frequency. Whether you want to raise or lower the natural frequency

depends on where it is, and how fast you are going. The reverse may be

true on the ES. Any reports from pilots?

One possibility: the longer wing and larger tail

surface of the ES make the airframe moment of inertia about the vertical axis

larger than it will be on the IV. The ES is more resistant to being

rotated around the vertical axis. If the oscillator behavior is

sensitive to the rotational tendency of the airframe (the strut and the

airframe wiggle together and could create coupled oscillators), the longer wing

would lower the oscillator frequency a bit. But this seems like an

unlikely source compared to other possibilities. And besides, there

is nothing we can do about it except be aware of it.

The third exception is fuel load. Having more

fuel increases the moment of inertia and reduces the natural frequency of the

fuselage around its vertical axis. And sloshing fuel adds

dampening. But I think this is a long shot and besides we can do nothing

about it.

Excitation forces

We have lots to work with here. Get rid of

them. Not entirely possible, of course, so minimize them. What

could they be?

1)

Nose wheel imbalance or out of round or uneven nose tire wear are

obvious causes and should be examined. The excitation force will generally be

the rotational speed of the tire and that will start from about 2200 RPM (36

cycles per second) down to zero (14 inch OD tire, 80 knots touchdown

speed). Anecdotal reports suggest the problems usually occur in the 20-40

knot speed range (to be verified) suggesting frequencies of 9 to 18 cycles per

second. Those kinds of numbers feel intuitively correct.

2)

Main gear imbalance: same thing. Imagine if both tires are out of

balance and they get 180 degrees out of phase so that they alternate in pulling

forward and backward. The main gear imbalance can cause the nose to

wiggle from side to side, and if that forcing frequency is just right, you get

resonance.

3)

Main gear braking action can be a problem for the same reason as main

gear imbalance, although the forces can potentially be much larger and independent

of rotational speed. Imagine a brake disk that is of variable

thickness. You will get wiggles as you brake and they will get worse the

harder you press. Reports suggest that going to high energy brakes can

help. Brake fade has been reported on low energy brakes. Brake fade comes

from high temperatures which create a lot of gas emission from the brake pad

which lubricates the pad/disk interface. Essentially gas pressure holds

the pad off the disk. Changes in the surface texture on the disk can

cause variability as the disk rotates because the gas escape and friction can

vary. High energy brakes substitute materials that reduce gas emission

rates, pad designs that let the gas escape and rotors that can take higher

temperatures without bad behavior. ES brakes maybe more subject to brake

fade than the IV because the rotors and calipers are inside the wheel pant and

can not cool as well. If the low energy brake disks warp from the higher

level of heating it could well contribute to increasing any exciting forces

coming from the main gear. Add this to wheel/tire imbalance, get

everything in the right phase, and these forces could be large enough to cause

problems, and also cause the airplane nose to bob up and down a bit as well.

4)

Nose gear caster angle creates self centering restoring forces that can

be both spring forces for an oscillator, and exiting forces for that same

oscillator. The caster angle clearly has to have some effect, and I

suspect the tire pressure does as well since a wiggling nose tire is making S

turns down the runway. As the nose wheel makes its S turns, more caster

angle will result in larger vertical forces as the tire to rotates around the

strut central axis. If the strut is not vertical viewed from the

front, there will be a continuing side force trying to turn the nose wheel.

This force and forces opposing it (to keep the airplane straight) could yield

excitation forces.

5)

Bumps from rocks and bumps on the runway create a one time hit to the

oscillator, like ringing a bell. If the shape of the pulse created has a

lot of energy at the natural frequency of the system, it could excite the

oscillator which otherwise may have remained quiescent during the deceleration.

But I think it would take a long bump. If the natural frequency

corresponds to, say, 30 knots (50 feet per second), an oscillation of 10 cycles

per second means one cycle consumes 5 feet of travel distance. A half wavelength

bump would 2.5 feet. Such a bump would contain a lot of energy at 10

cycles per second. But 2.5 to 5 feet seems to suggest a single tire

rotation more than a bump. But things can add up.

Dampening

Here again we have something to work with.

1)

Strut oil is the obvious target. Anecdotal evidence suggests that

hot struts thin oil and reduce dampening to the point that shimmy can

occur. On the IV, the strut is baked under the engine during flight, but

cools somewhat during descent, and then is cooled a lot when the gear is

extended. Is 3-5 minutes enough time to bring the oil temperature in the hot

strut down close to ambient while you motor around the pattern? I think

so given the 100 knot cooling blast. So controlling strut heating by

preventing hot air flow down the strut fairing seems worthwhile. Higher

viscosity oil should help as well, but watch out in Minnesota in the winter.

2)

There is dampening in the nose tire patch that contacts the runway,

particularly if the nose wheel starts to make fast S turns. A bigger tire

patch from lower pressure would seem to help.

3)

There is also dampening in structure: strut, strut to engine mount

connection, engine mount dampening (probably very low for the stiff welded

structure) and perhaps even some effect from the elastic engine mounts as the nose

gear shimmies under the engine mass. But there is not much we can do

except to check that everything is tight.

Checklist

This discussion suggests a checklist that would

include the following:

1)

Tire balance, mains as well as nose wheel. And check that they are

round and not unevenly worn.

2)

Brake pulsations caused by warped or variable thickness disks that may

have been overheated. Substituting high energy brakes or maybe just a

resurfacing of the brake rotor could help.

3)

Keep the strut cooler by blocking hot airflow down the strut, or

increase the viscosity of the oil. Lancair IV drivers could put the gear

down earlier, particularly on a hot day, to provide for more strut cooling.

4)

Check the strut and engine mount structure for free play. Make

sure everything is tight

5)

Look for cracks on the engine mount. These can change the spring

rate and natural frequency which may worsen the tendency to shimmy.

6)

Adjust nose tire pressure, probably downward.

7)

Check strut to make sure it is vertical viewed from the front.

My guess is that those with persistent shimmy problems

probably have several factors at work that sometimes work together to create

the shimmy. Corrective action in several places will be required.

Suggestions

I suggest that some enthusiastic ES builder compile a

big table of evidence from the ES community, those that have shimmy problems and

those that do not. Record as much information as possible in a consistent

format. I suggest listing subject columns across the top, and builder

name and incident down the left side. Multiple incidents from the same

builder would be recorded separately. Column subjects would be those areas

identified above: Tire balance and roundness, tire pressure, brake condition,

strut cooled or not, speed when shimmy occurs, control wheel forward or aft

during shimmy, OAT when problem occurred, CG location (which affects strut

extension), oil used, and any stray comments. Not every report will

record all data, but something is better than nothing.

I bet that once this process is begun and the various

incidents and conditions are recorded, the patterns will become clear and

suggest which the big contributors to shimmy are, and which are smaller but

still can make a difference.

Be sure to share the results with all the rest of us!

I hope this helps. It is a good exercise for

the little gray cells.

Fred Moreno