|

|

2) Is it just me, or is the distance between the trim tab servo

output arm and the trim tab actuator going to come out so small that

you can't fit two of those clevises?

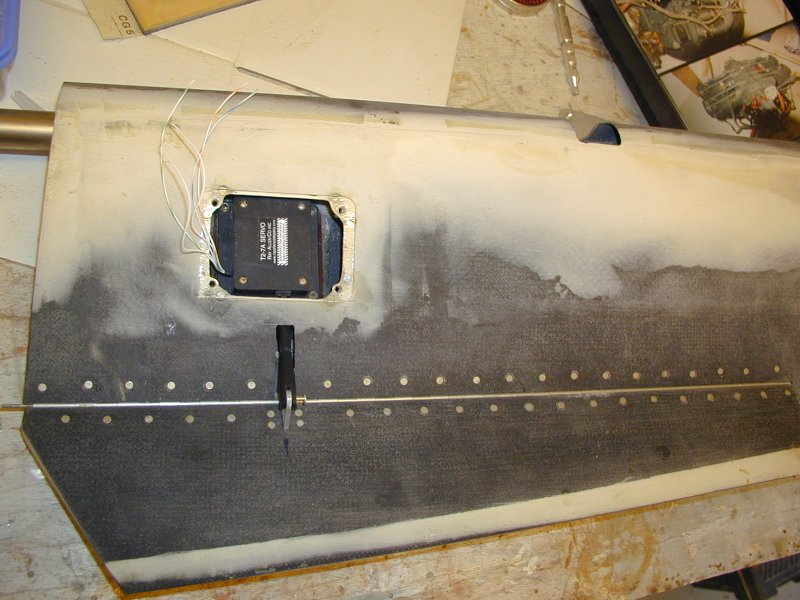

Here is a photo of my installation.

Don´t trust the manual. My bottom skin had a built-in recess that fit

the servo motor pretty accurate. I figured that this recess was made so

that the servo, when installed from the bottom, would make out the

cover for the access hole. No word about this in the manual, so I

called Josh at the factory to get things sorted out.

According to Josh, there were no specific rules about the issue, I

could basically suit myself.............. Sometimes this recess was

made in the bottom skin and sometimes in the upper skin............

Anyway, I asked if it would be ok to install the servo in the bottom

skin and still have the control horn on the bottom as well. This would

be ok, suit yourself............ I tried it, but the angle of the

pushrod came out at some 30 deg. or so, which induced severe bending

forces on the servo arm and, thus, a lot of slack in the trim system.

Not acceptable. I finally had to install the servo on the inside of the

upper skin and simply cut out the recess in the bottom skin (it was too

small to allow installation of the 1/8" phenolic and mounting screws)

and make a cover plate. This seems like an ok solution, but I had to

buy a T2-7A servo (0.75" stroke vs. 1.0" for the recommended servo) to

get the req´d 25 deg. (I think) servo deflection in both directions. I

did some experimenting with a longer control horn but, again, the angle

of the push rod became excessive.

As I recall it, I did not shorten the clevises. I just skipped the

safety nuts. The threaded piece has a very strong selv locking effect

when bottomed out in the clevises and the clevises cannot turn. No need

for safety wire or lock nuts here.

Very best regards

Tim Jorgensen

360MKIIFB / 60%

Elevator.jpg

|

|