It's been a log time since I

built/modified my 13B back in 1999, so someone please remind me.

I thought the pellet was in the end of

the e-shaft with a spring pushing on it and one replaced the

spring with a spacer? You're saying it's accessible from the side

of the e-shaft with the oil pan removed?

I understand the e-shaft jets may be

accessible from the bottom with the oil pan removed.

Hey there Andrew.

Thanks mate, good thinking.

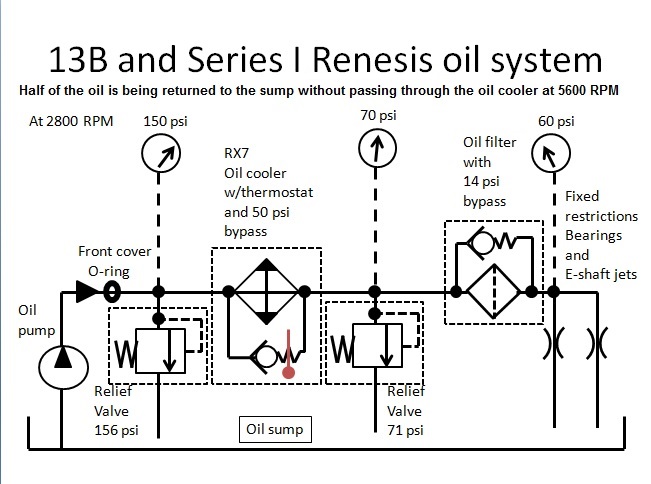

I found this schematic.

If I tap in and check the pressure leaving the engine

(pump-relief valve) it would give me an idea if I have a problem

there which is my hunch.

The Schematic suggests that I should see about 150 psi at

2800 rpm. Though I read a forum where Lynn Hanover said the

lowest pressure pump bypasses were set at 110 psi.

My cooler is a 44 row Mocal which I’m thinking will present

lower restriction than the Renesis single cooler setup.

I do filter all oil after the cooler as opposed to the OEM

setup which only filters oil going into the engine bearings and

eccentric.

I use a race filter so hopefully not to higher restriction

but maybe higher due to the above mentioned.

I did do the thermal pellet delete as you did but I didn’t

mod the eccentric jets.

I’m wondering if I might be able to remove the pan and then

the front cover while in the aircraft. It will be tight, but

prefer to not disassemble th prop, gearbox and many other

systems.

With the pan off I can check a number of key things.

1. The thermal pellet delete. Via the hole in the eccentric

shaft. Should be blocked by the aluminium piece Tracy provided.

2. The front relief valve spring and cracking pressure using

a spare front cover Ive got.

3. The Rear relief valve cracking pressure.

4. Maybe even the o-ring seal

I know I need to be very careful of not messing up the

components on the front of the eccentric. I do need to

understand this properly before remove the front cover.

My money is still on the gasket/o-rng seal between the front

iron and cover being damaged at first start up.

Thanks mate.

Steve

Hi Steve. I think we got same engine as you. Been

awhile since I operated it so memory may be wrong. But

pretty sure it sits on 80psi.

I did the thermal pellet delete mod

during the original build. it was a part that Tracey

supplied with all the other bits. You may be lucky

enough to have enough room to do this mod while

engine is mounted in the plane. Some people modified

the eshaft jets to increase oil to rotors, this I

assume would lower oil pressure also. I did not do

this.

For series 1 Renesis only.

I would first check pressure at front

cover oil port, relief in there is set to something

like 125psi to protect the pump from blocked cooler,

if you plumbed a gauge and a needle valve in

series(or, if your game, clamp the hose) you could

gradually restrict oil flow until relief opens. This

confirms that everything at front cover end is ok. A

difference in pressure at front cover & rear

iron sensor indicates pressure drop through cooler,

hoses & filter(if other than OEM). This does not

matter too much unless your seeing front cover

relief pressure at lower than your operating rpm.

Next place to look requires engine

teardown.

Andrew

Hi

again Finn

A qualification. Mazda used a lower oil pressure

for the Renesis Series 1 than previous engine

series, and then went back to higher pressure for

the series 2 Renesis.

My understanding is that the thermal pellet in the

front end of the Eccentric Shaft, when cold is

open allowing the oil to dump into the pan rather

than when warmed up it closes and the oil in the

eccentric now squirts into the rotors cooling

them.

I believe this is about emission control at

startup and that for racing and our use, better to

delete this thermostat and block permanently this

path meaning oil is always cooling the rotors.

If the thermal pellet fails, it does so open and

so stopping the rotor oil cooling. Not a good

thing and can cook the oil o-rings on the rotor

sides.

Open to being corrected.

Steve

> On 1 Nov 2024, at 10:50 pm, Stephen Izett stephen.izett@gmail.com

<flyrotary@lancaironline.net>

wrote:

>

> Thanks Finn.

>

> I should have mentioned the first thing I did

was put a gauge to check the EFIS reported oil

pressure. They were both reading within 2psi so I

have taken it to be accurate to within about 2

psi.

> Thanks for the data.

>

> Steve

>

>

>> On 1 Nov 2024, at 9:23 pm, Finn Lassen finn.lassen@verizon.net

<flyrotary@lancaironline.net>

wrote:

>>

>> Startup oil pressure depends a bit on

OAT.

>> Recent example: OAT 82, oil pressure 80 @

2,700 RPM dropping as low as 50 @ 2,300 RPM after

80 seconds.

>> 67 @ 5,900 RPM during takeoff climb.

(Over propped.)

>> Cruising along 68 psi @ 5,200 RPM, 62

OAT, 4,000'

>>

>> Sampling some logs I found 74 psi @ 6,500

RPM.

>>

>> I would say the relief valve is somewhere

between 80 and 90 psi. Normally runs at 60 - 70

psi.

>>

>> Factory (unopened) Renesis 4 -port, I

guess series 1. I don't know what happens when you

replace the pellet with something else.

>>

>> I too had heard that the Renesis ran at

higher oil pressures and foolishly ordered and

installed a 150 psi oil pressure sensor.

>>

>> I guess 50 psi sounds a bit low at higher

RPMs. Check the sensor for accuracy.

>>

>> Finn

>>

>>

>>

>> On 11/1/2024 8:17 AM, Stephen Izett stephen.izett@gmail.com

wrote:

>>> Hi People.

>>>

>>> Could I pick your brains.

>>>

>>> I’ve been flying a Series 1 Renesis 4

port in the Glasair for some years now.

>>> I have always thought the oil

pressure was a bit low but I’ve now got some

concerns and would appreciate any wisdom.

>>>

>>> I’ve read that the Series 1 Renesis

has lower Oil pressure than the previous rotaries

and then the Series 2 had the pressure increased.

>>> Some have changed the rear iron

relief valve for an older series with a high

bypass pressure and then shimmed the front cover

relief valve to enable a higher pressure.

>>>

>>> Ours has always had a cold start

pressure (measured at the back iron oil input) of

around 64 psi that drops to around 50 psi when

warm.

>>> What I hadn’t realised was that it

sounds like normal behaviour is for oil pressure

to rise with RPM to a significantly higher value

at say 7000rpm. Higher in earlier and Series 2

Renesis with the Series 1 at a lower peak

pressure.

>>> Our engine doesn’t rise above that

initial cold start pressure of about 64 psi and

then not above 50 psi even at 7000rpm.

>>>

>>> If this is correct then it must have

oil bypassing back to the pan somewhere. A rotary

expert here says it sound like an engine with worn

bearings. But it’s always been like this when I

purchased it as one of the Mazda test engines and

looked like new,

>>> Points that it could bypass back to

the pan include:

>>> 1. O-ring / gasket between front iron

oil passage to front cover.

>>> 2. Front Iron relief valve.

>>> 3. Rear Iron relief valve.

>>> 4. Bearings worn.

>>> 5. E-Shalf thermal delete leak. (I

replaced the thermal pellet with Tracy’s Solid

Aluminium units)

>>>

>>> I recall that on its first ever start

we had a leak in the intake manifold and it burst

into life at hight rpm and blew the oil filter

seal out.

>>> This leaves me wondering about that

front iron to front plate seal. Is this a gasket

or o-ring in the Renesis Series 1?

>>>

>>> Is there any Renesis Series 1 engines

out there and can I get your numbers and

experience?

>>> I’m wondering is 50 psi at 7200

dangerous for the bearings, rotors?

>>>

>>>

>>> Thanks

>>>

>>> Steve

>>> Perth Western Australia

>>>

>>> Glasair Super II RG Genesis 4 port

RD1C EC/EM

>>>

>>>

>>>

>>>

>>>

>>>

>>> .

>>>

>>>

>>>

>>>

>>>

>>> --

>>> Homepage: http://www.flyrotary.com/

>>> Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

>>

>>

>>

>>

>> --

>> Homepage: http://www.flyrotary.com/

>> Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

>

>

>

> --

> Homepage: http://www.flyrotary.com/

> Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

--

Homepage: http://www.flyrotary.com/

Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html