|

|

It's been a while (north of 40 years),

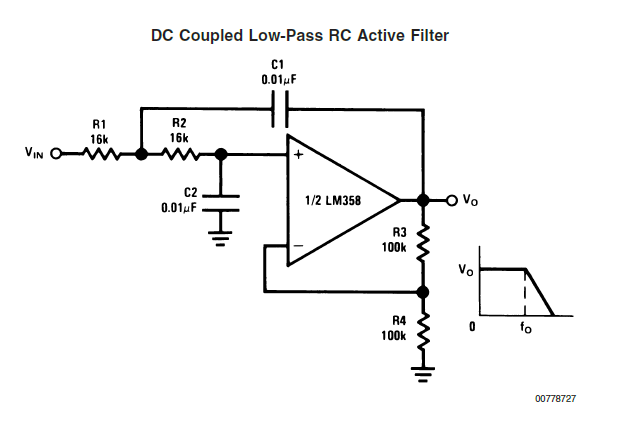

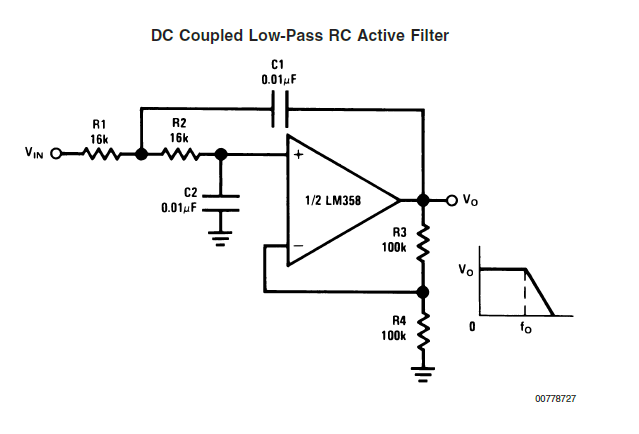

but IIRC, and you're using the circuit on the National datasheet,

I think it's a 12dB/octave filter. Each R/C pair should be 6dB

slope.

R4 not grounded....?? It's been way too long; not sure what would

happen if R4 is left floating. Infinite (open loop) gain?

On 3/19/2021 10:03 AM, Finn Lassen finn.lassen@verizon.net wrote:

Found a

soldering error on my circuit. So only 100x amplification and a Q

of 0.5 on the RC filter (not sure what that translates to in

dB/octave).

(LM358 datasheet "DC-coupled low-pass RC active filter). R4 not

connected to ground. A = 1 + R3/R4. Q = 1/(3 - A). What does a

negative Q mean? Unfortunately with A = 3 filter starts

oscillating. So need to lower or increase filter amplification.

Well, if there are two combustion events per rotation the

near-sine curve doesn't make any sense. Then there should be two

cycles between trigger pulses. If not combustion-related then a

weight on one of the four bolts should have reduced amplitude

somewhat, but on each bolt it got worse but didn't influence the

curve much. Now I have no idea what the curve comes from.

I like the old school idea.

As for flying off the hours and then flying to your place, the

reason I'm revisiting balancing now is that on my last flight I

noticed a vibration at 144 mph and 5,600 RPM. Took the prop off to

recheck static balance (didn't note where to put washers when I

last did it months ago). With the prop off, I thought I might try

to check engine balance (You mentioned reports of problems

balancing geared Rotax and Steve had mentioned that he first

balanced the engine, then the prop.) A week later I'm into filter

theory, FFT (spectrum analysis) and so on, trying to make my own

instrumentation and balancer. Typical for me :(

Should probably just have remounted the prop with the washers

needed from static balancing and gone flying. Oh, well...

Then there's cooling. Tracy thinks my rad coolant deltas are still

to big. Need to get rid of 90 deg elbow in return line from one

rad and another in the supply to the other rad. Then there's oil

and fuel leaks ... What to do first?

Finn

On 3/18/2021 7:38 PM, Charlie England ceengland7@gmail.com wrote:

Each rotor fires once per rev, so the

engine has one torque pulse every 180 degrees of E-shaft

rotation.

If the sine wave might be combustion related, can you move the

sensor array (both trigger and vibe sensor) 90 degrees &

compare timing of the peaks to the original configuration? If

it's combustion events, then sine wave will 'move' 90* earlier

or later related to the trigger point. If it's actual imbalance,

the peak should follow the sensor array.

Filter frequencies are typically spec'd at the -3dB 'knee'

point. So if the filter was constructed based on frequency 'x',

then rolloff will start significantly sooner than the spec freq.

How much sooner depends on what 'order' the filter is. 1st order

(6 dB/octave) will begin to roll off *much* earlier, removing

more in-band and *not* filter out as much out-of-band as a 3rd

order filter (18 dB/octave), which has a much steeper slope. If

you want to avoid affecting in-band levels, the cutoff must be

significantly out of band. See the 'Butterworth' filter graph on

Wikipedia. https://en.wikipedia.org/wiki/Low-pass_filter

Have you thought about going 'old school' with balancing? Rig

one of your LED landing lights to trigger off the peak pulse of

the ADXL335, put a 'witness mark' on the face of the flywheel,

and the strobe will show you the rotational position of the

flywheel when the ADXL335 feels the peak out-of-balance.

Or, you could let an A&P do it. Or get on with flying your

time off, and then fly it up here; I've got our EAA chapter's

Dynavibe in my hangar...

Charlie

On 3/18/2021 3:38 PM, Finn Lassen finn.lassen@verizon.net wrote:

LED and photo transistor in same

housing. I put it inside a 1/2" CPVC tube so I can't read the

part number.

In an ideal world, a mass rotating around a center point

should produce a sine curve. But what if you have more than

one mass? You should be able to use vector math to find the

resulting single equivalent mass.

However, looks like a combustion engine is not that simple.

I'm now fairly confident that the near-sine curve I see on the

scope is mainly the combustion event. Someone need to refresh

my memory: how many times does combustion occur per flywheel

rotation? Looks to me like one. Rotor 1, then next rotation

rotor 2, then next rotation the next surface of rotor 1, etc.

Is that right?

To make matters worse, you also have other sources of

vibration: alternator, water pump, etc. Their vibrations

(different frequencies) are added to the basic one period per

flywheel sine curve. If I'm right, the combustion event won't

be a simple sine curve either: a pulse resolves into multiple

frequencies (spectrum).

When you look at a scope the signal is not stable: any little

misfire will jar it up or down. Makes is really hard to read

amplitude on scope.

In theory, a real effective low pass filter should remove all

other frequencies than the one you're interested in but

doesn't seem to work all that well in practice. So, back to

FFT on my Arduino Nano. Basically using FFT to produce a

frequency spectrum.

My Arduino program takes 128 samples with a sampling frequency

of 300 Hz. Sampling starts at the trigger pulse (may or may

not be a good idea). This is repeated 8 times and averages

calculated. Then the FFT transforms the 128 sample values into

64 frequency "bins", the magnitude of each are then plotted.

Using Ernest's method, I took 5 readings (no nut, then a 1/4"

lock nut zip-tied to each bolt nut in turn), running engine at

or just below 3,000 RPM (50Hz). (Varied RPM slightly using

mixture knob to ensure got result in the 50 Hz bin only)

(Basically using the FFT as a band-pass filter.)

Result was that the 4.4g weight worsened the amplitude at bolt

1, 2, 3 and 4.

No nut: 5-10 (varying between 5 and 10 on successive plots)

Bolt 1: 20-22

Bolt 2: 18-20

Bolt 3: 30

Bolt 4: 20-22

So if adding a 4.4g weight increases vibration at least by a

factor 2 no matter where it's added, I decided that's good

enough, removed it and called it quits. Onto prop balancing.

(Except, should probably remove the PSRU and replace the oil

seal now that the prop is off ...)

Now, my circuitry doesn't match theory. The LP filter op-amp

should have had a 3x amplification and 3db frequency at 120

Hz. A following op-amp should have 100x amplification. Hooked

up a generator to the input instead of the ADXL335 and

measured input and output. Filter amp has no amplification and

the filter seems to cut in way lower than 120Hz. The following

op-amp only seemed to have 80 to 90x amplification. I should

probably use low-noise op-amps as Charlie suggested instead of

the LM358. The LM358 runs on single-supply voltage (5V) but

that requires caps between filter output and amplifier input.

I guess I should make a schematic and submit for critique. Got

the theory from my electronic tech apprenticeship papers back

in 70's.

As for measuring phase or angle on the scope, sort of can be

done. But again, this is not an electric motor!

Also the FFT gives both amplitude and phase info for each

frequency "bin", but I have not been able to relate that to

the trigger pulse. Hmmm, now I think I get it. Supposed to

have two channels being sampled simultaneously: one the

trigger pulse, two the accelerometer. Not sure I want to spend

more time on it at the moment. The "nut" methods appear a lot

simpler (although require more runs).

Finn

---

This email has been checked for viruses by Avast antivirus

software.

https://www.avast.com/antivirus

--

Homepage: http://www.flyrotary.com/

Archive and UnSub:

http://mail.lancaironline.net:81/lists/flyrotary/List.html

hlfcohnmdibepicp.png

|

|