|

|

In a message dated 11/28/2002 1:11:31 AM US Eastern Standard Time,

lors01@msn.com writes:

> While I've been playing with the cooling system measurements, I decided to

> look into a nagging symptom that I've had since building the airplane. The

> cooling system has never remained completely topped off and seemed to loose

> a small amount of coolant (~ 2 oz) on every flight. This didn't seem to be

> a problem because the cooling system works OK until its about two quarts

low

> and I check and top off the system long before that happens.

>

> I have a one quart overflow bottle which is about the only size the

> aftermarket brands offer (I used Moroso) so I assumed this was adequate for

> any installation. To test this, I ran the hose from the overflow port on

> the overflow bottle to the cockpit and connected it to a second bottle.

> Sure enough, when the engine got up to full operating temperature, the hose

> puked a couple of ounces into the second bottle. When the engine cooled

to

> room temperature, it recovered all the coolant in the first bottle then

> sucked in a bit of air.

>

> Moral of the story: Use a coolant recovery bottle larger than 1 quart. I

> just installed a 1.5 liter bottle. Will flight test this setup tomorrow.

>

> I also noticed that cooling was noticeably better when the system was

> completely full of liquid with absolutely no air in it. Even a few ounces

> worth of air in the system caused the coolant temp to go up about 5 - 7

> degrees. The amount of air did not seem to affect it much. Anything from 3

> oz to 60 oz of missing coolant has the same effect on temperature. I don't

> know the exact cause of this temp increase. More than 60 oz missing causes

> the temps to rise rapidly (I think the pump starts sucking air at this

> level).

>

> Tracy Crook

> tcrook@rotaryaviation.com

> www.rotaryaviation.com

>

I have a recovery bottle from an RX-2 connected between the water outlet and

the radiator. Once I have heat cycled the engine a few times, I keep adding

coolant until I have the bottle 1/4 full. After that there is no loss of

fluid. I have a catch tank connected to the outlet on the RX-2 bottle but it

never gets anything in it. I have the hose connection to the catch tank near

the top so it cannot recover any dumped coolant. This way I can look into the

catch tank and be sure all is well without opening my pressurized system. I

have a Shrader valve installed in the RX-2 recovery bottle so that I can

pressurize the coolant before I start the engine. The Stant 16 pound lever

cap on the recovery bottle will hold pressure for weeks on end so long as the

cap and seat are in good condition. The coolant pressure inside the engine

will be dependent on a number of conditions in the coolant loop. The pumps

are oversized so as to perform well in the worst case situation.

Unrestricted, the pump can circulate an enormous amount of coolant through

the system. If there is no thermostat or restrictor in the exit from the

block, there will be high flow rate and the radiator(s) will be the

restriction. High pressure will exist between engine out and radiator in. The

top hoses will be very hard at full RPM. The suction side of the pump my drop

below 1 bar and some cavitation may occur. Dissolved gasses may be liberated

on the suction side of the pump and may not be reentrained quickly on the

pressure side. Then you have a bit more pressure than your pressure cap will

contain. On shutdown, the gasses are reabsorbed and all is well, less the

small amount dumped into your catch tank. The pressure generated by the pump

can be well above what even a 22 pound racing cap can contain. So, the

location of the connection between the system and the recovery bottle can

cause a problem. Between the engine and the radiator will be the highest

pressure in the system. It is also the most popular location for this

connection. As in the case where a car radiator has the pressure cap on the

radiator tank. But cars have thermostats in them. In addition to being a

temperature actuated valve, a thermostat is also a restrictor. A sharp edged

hole with a sharp edged disc hovering above it. Very bad for flow. So even

when wide open it creates a terrible flow restriction that raises the

pressure in the block, (all good news) and lowers pressure in the upper

radiator hoses and in most cases pressure going to the recovery bottle. (more

good news).

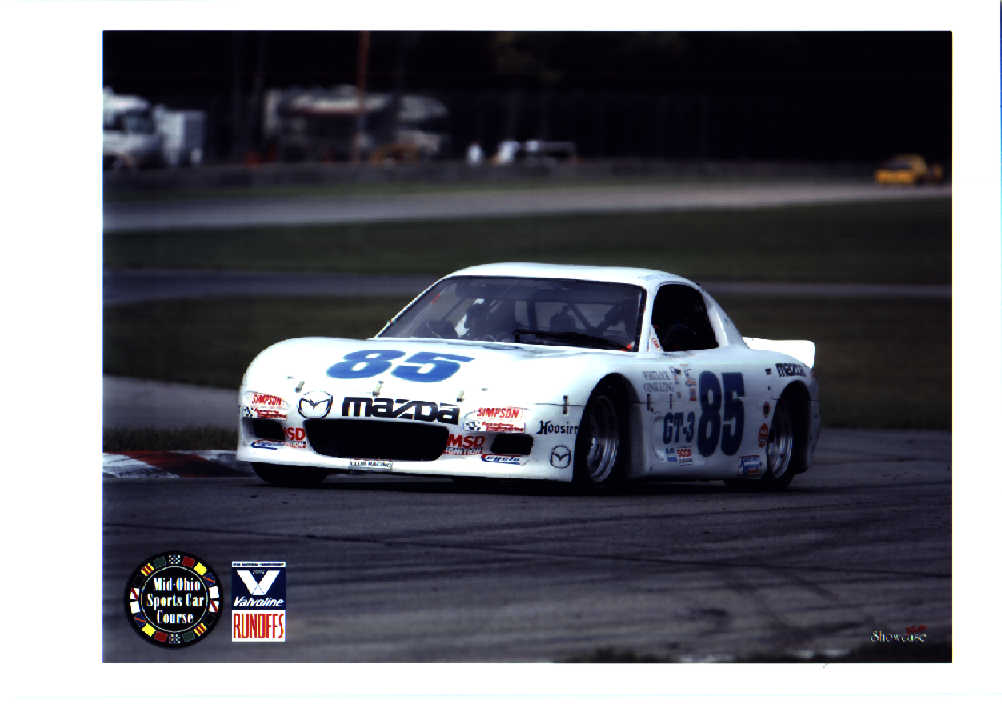

I do run a thermostat in cool weather. I have a plate welded over the water

outlet casting on top of the water pump. All of the water that cools my race

engine must pass through a 5/8" sharp edged hole in this plate. My connection

to the recovery bottle is down stream from the 5/8" restriction. I have no

cooling problems at all since I started racing rotaries in 1980. My engine

does not overheat and does not dump coolant into my catch tank. My recovery

bottle has a 16 pound Stant lever cap.

For airplane use I would go to 22 pounds just to be sure.

Lynn E. Hanover

RunoffsRH_WEB.jpg

|

|