Finn, either you live in the tropics or like shoveling snow …

No comments about the wind calculations, but if living in a snow-belt the horizontal bi-fold doors are simply the best.

Vertical folding doors require shoveling and ice-chipping the entire width of the hangar just to get the doors open, then another 15 foot swath on the ramp

out to the taxiway to get the airplane out. I will say, the narrow 3 foot vertical sections you propose are significantly better than the typical 10’x4 sections commonly used.

Jeff

From: Finn Lassen [mailto:finn.lassen@verizon.net]

Sent: Wednesday, December 29, 2010 12:46 AM

Subject: Off topic: Hangar doors

Looking to design and build hangar doors.

I kinda fancy vertical harmonica doors.

/\/\/\/\/\

The inner points carried by wheels in groove in concrete slab.

Wheels able to pivot in bottom of door frames.

Top supported by rollers in a steel U-channel, able to pivot in top of door frames.

I figure 3 feet wide sections hinged at edges.

The thinner the better, but will have to be able to withstand wind pressure without deforming.

10 feet tall.

Max wind pressure 31 pounds/sq ft. (110 mph wind zone).

Obviously that's on the high side. There are trees in the vicinity. So 20 pounds/sq ft may be a more realistic number. But it doesn't hurt to be on the safe side,

For calculations the vertical supports will be spaced 1.5 feet apart. (Actually 3 feet apart but doubled at each edge).

I'm figuring maximum of 450 pounds of distributed weight (wind pressure) on each vertical support.

I've seen a couple of different formulas for maximum deflection, for example:

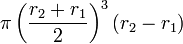

5/384 * W * L^3 / (E * I).

I assume I can safely use E = 30,000,000 for steel.

Let's say I'll allow 3" maximum deflection:

I = 0.113?

However, I'm having trouble arriving at values for I (area moment of inertia).

What would I be for a 2"x2" 1/8" wall square steel tube?

|

|

|

|

(2 * 2^3) / 12 = 1.33?

Or would that only be for a solid 2x2" bar?

For a 1.5" square tube?

I = 0.42?

(I also need guard railing for my porch. Seems a1.5"D tube with 1/8" wall is I = 0.1276.

Does that seem right?)

Also, I guess I'm not so much concerned with deflection as with point of permanent deformation.

How would I arrive at that number?

My objective is the thin hangar doors and the lightest guard rails. And of course cheapest materials.

Sanity check appreciated.

Finn

__________ Information from ESET NOD32 Antivirus, version of virus signature database 5741 (20101229) __________

The message was checked by ESET NOD32 Antivirus.

http://www.eset.com