|

|

George, Let me get this straight.........Steel tube TIG welded to steel insert.......Then aluminum insert with O-ring (s) to seal to the steel tube.......? A sketch would be worth a thousand words for the engineering challenged........ --

Kelly Troyer

I would advise against welding anything to the liner. The housings are actually very flexible, and will soon warp in favor of the weld beads. A thick walled aluminum tube in a very light press fit through the inner wall. Same through the outer wall, but not tight through the outer wall is also fine. The inner wall needs good support to prevent chrome cracking when you torque up the stack. Lynn E. Hanover

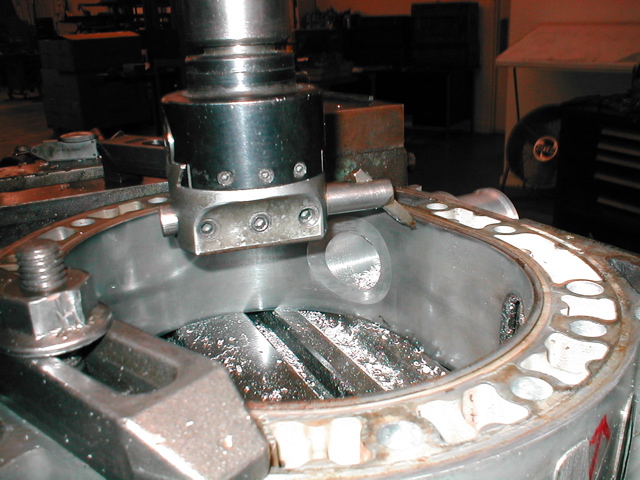

Lynn, similar to this? My inserts(throttle bodies). They are 2.25 o.d. and 1.5 i.d. 6061 T6 Jerry

unknown.jpg

|

|